Company News, Product Updates, Feature Highlights, Articles, News

Introducing Backlog, By Slabstack

For heavy materials producers, quoting isn’t just paperwork — it’s the front line of margin protection and growth. Slabstack has helped many producers replace manual quoting and generic CRMs with a purpose-built sales and pricing engine designed specifically for construction materials. Today, with 90+ customers, 1,000+...

18 Feb 2026

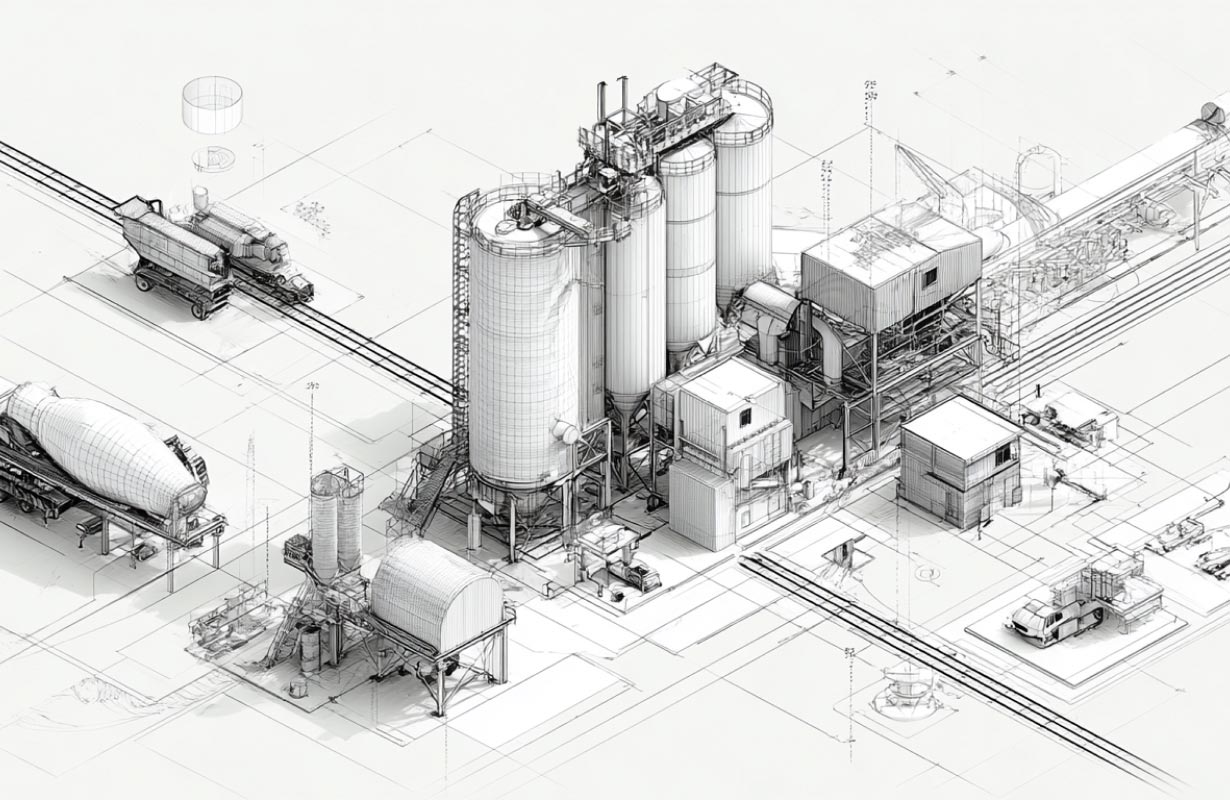

The fastest path to smarter concrete starts here.

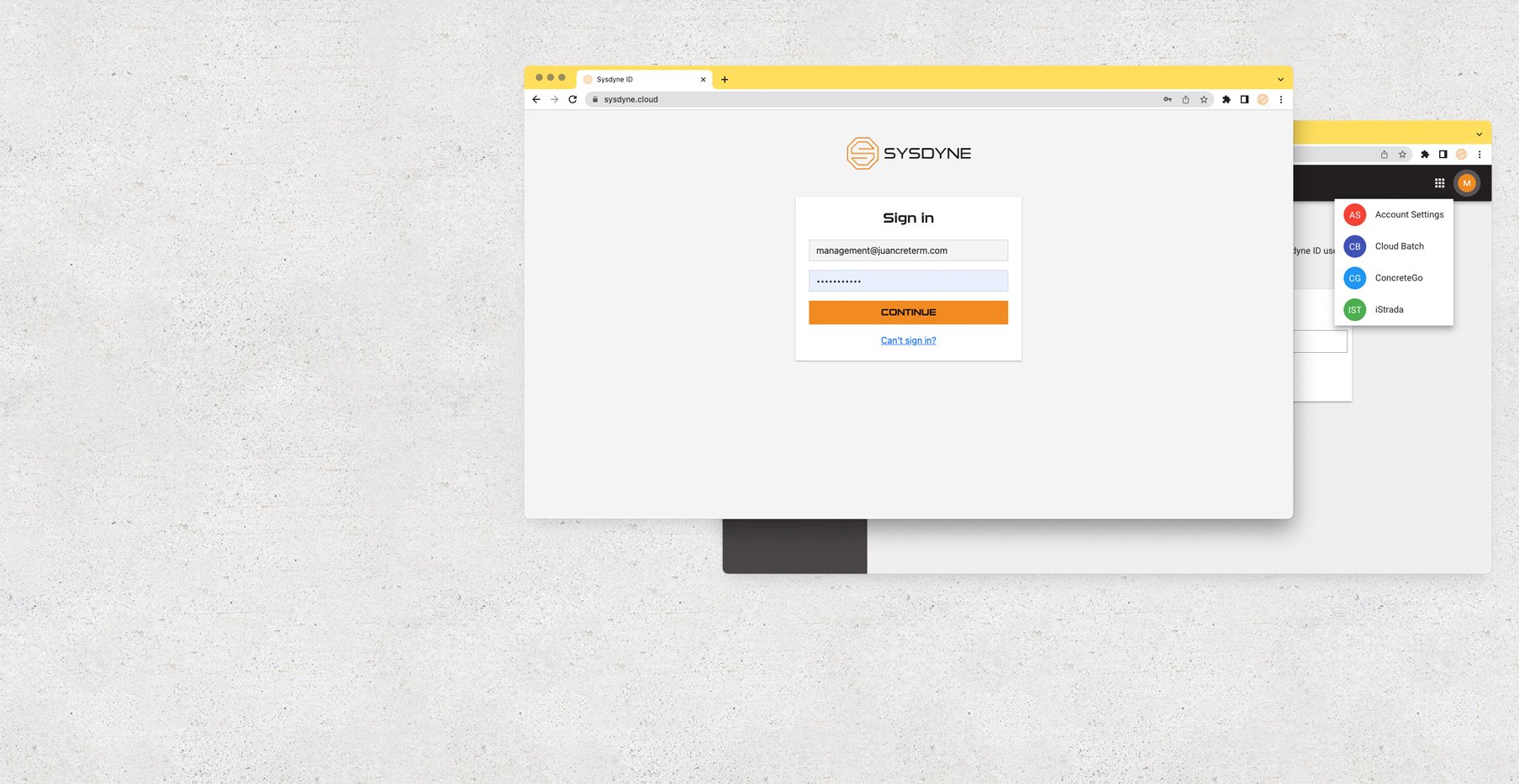

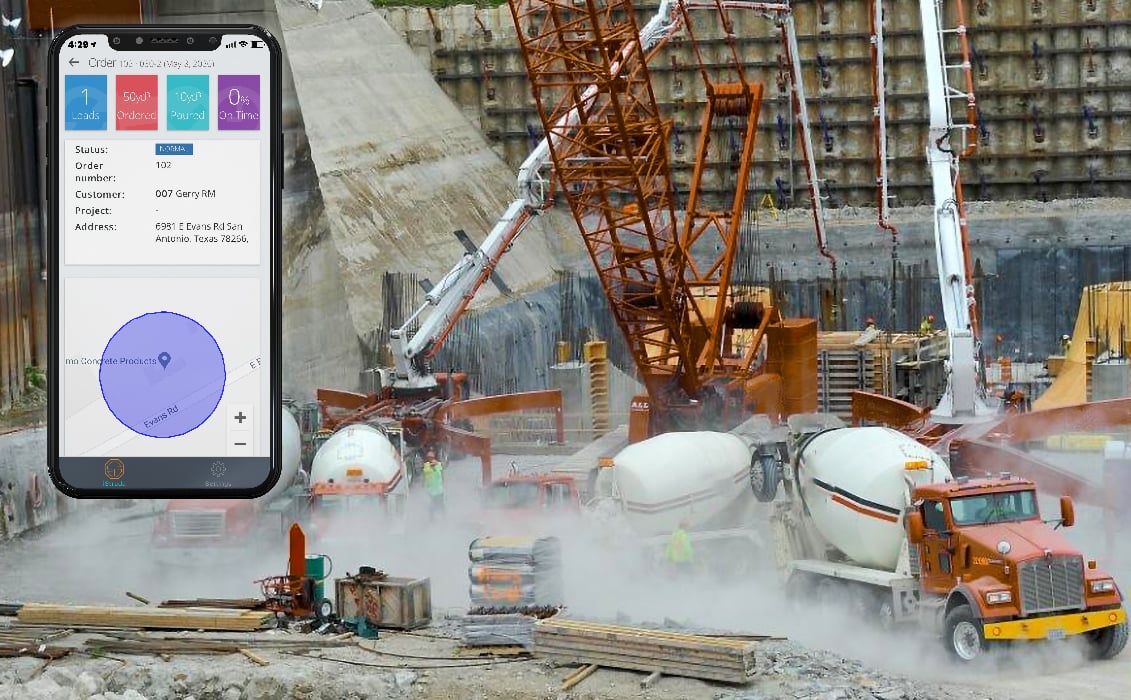

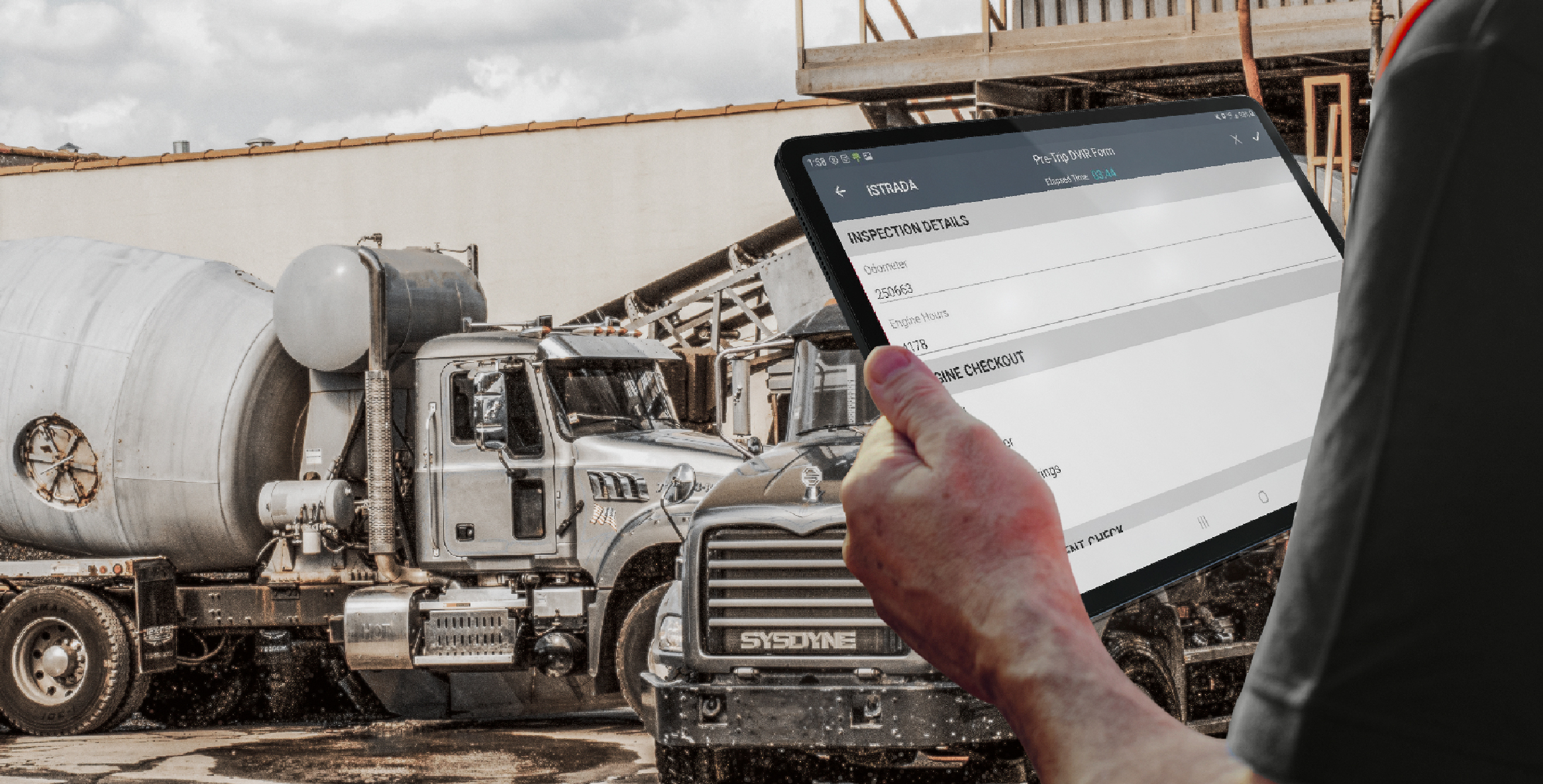

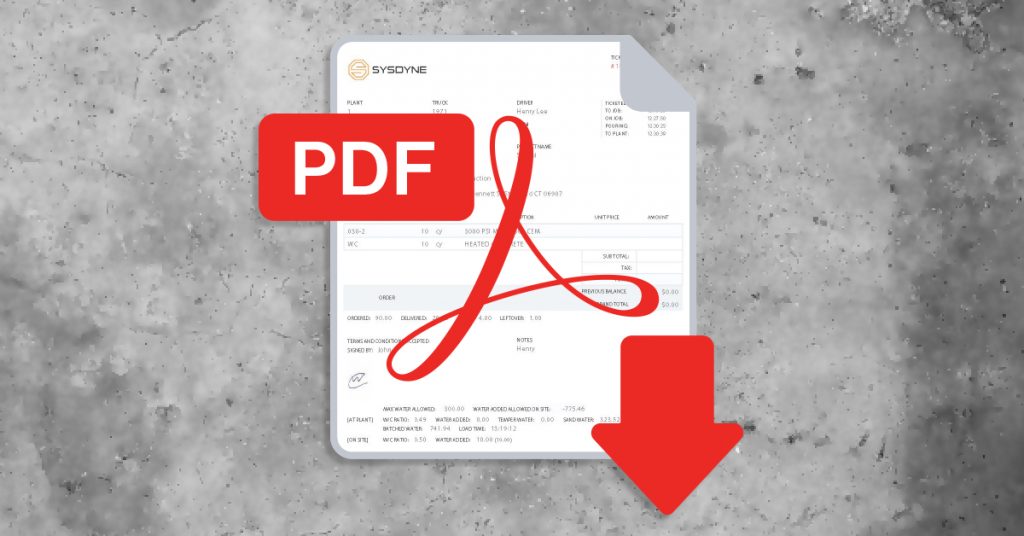

Sysdyne connects with the tools you already use — so the team saves time, and business runs smoother. From quality control and mix design to business intelligence and optimization, Sysdyne supports all your integrations.