Innovation in the Construction industry: How Using Big Data Can Benefit Ready-Mix Producers

Let’s Begin With the Question: What is Big Data?

Big Data is a term that describes the large volume of data – both structured and unstructured – that inundates a business on a day-to-day basis. The volume of data is so large that it’s difficult or almost impossible to process using traditional methods. By taking advantage of the detailed information available through Big Data, Concrete Producers are provided the ability to generate better business insights and improve their bottom line. Big Data drives the ability to better understand business processes, operational efficiency, and customer interaction.

Coupled with analytics, Big Data provides the power needed to make well-informed business decisions.

In the Construction Industry, Big Data typically refers to large quantities of information that is stored as historical data but continues to grow in size. The data itself can come from people, computers, machines, sensors, and any other data-generating devices. Think of the amount of historical data that gets processed to then be shelved away in boxes over time – Has this data lost its value? The answer lies in our ability to easily access and analyze the data's relevance to make an informed decision. For example, analyzing historical bid information and correlating the results with other data sets like competition and job location to build estimates that have a higher percentage of winning. Another example is using Sysdyne CloudBatch™ database for both concrete Batch and Dispatch. Using a single database to house scheduling, delivery, and batch performance data to measure efficiency and profitability provides tremendous value to Producers. Other considerations, such as monitoring material consumption using real-time inventory, allows Concrete Producers to track and anticipate material shortages and make adjustments to save material costs. Inventory is automatically updated as batch operators record material receipts and load concrete using CloudBatch™.

As IoT (Internet of Things) becomes more prevalent within the construction industry, all data generated needs to be organized and stored in an accessible location for it to yield any real value.

A further example of leveraging Big Data in the concrete industry is the growing popularity of installing dashcams in concrete mixer trucks to track driver behavior. These large volumes of data made of video events and alerts offer tremendous value when cross-referenced with information from other data sets like concrete delivery metrics and using paperless ticketing. Combining Delivery KPI information and video intelligence on the digital ticket provides easy access to actionable data to help improve fleet safety and concrete delivery performance. Using collaboration platforms like Sysdyne’s iStrada Lytx machine vision and AI-powered fleet dashcam solution, producers can monitor driver behavior, monitor delivery performance metrics including yards poured/delivered/remaining, and track job acceptance on paperless digital tickets. As data gets bigger and bigger, the need to boil it down to the actionable essentials gets bigger as well. Big Data sets like video logs from dashcams and live feeds from sensors on plants or trucks can add up quickly. This is where tackling Big Data becomes vital; cloud computing coupled with robust analytic platforms to crunch the data and provide value is an important part of the solution. The variety of inputs in Big Data allows better levels of certainty about status reports and production forecasts. The analytics can provide more helpful indications of risk levels before a threshold is exceeded and an alert generated. For example, using IoT (Internet of Things) to place sensors on plant equipment can offer endless possibilities in preventing mechanical failures that would otherwise shut the plant down and stop production – Hence the idea that of preventive plant maintenance can begin to take shape powered by analytics in the batch software to alert production managers of potential problems before they happen. Much like using GPS to track trucks on a digital map has, the next wave of industrial sensors to power our thirst for real-time data to better manage our assets will become the norm. Harnessing Big Data will continue to offer insights that traditional methods and systems simply cannot. Traditional methods are good at compiling and storing data about everything from production statistics to delivery metrics and profitability. However, they are limited in their ability to work with unstructured data like free text, printed information, or analog sensor readings. The idea of harnessing Big Data is to gain more insights and make better decisions by analyzing a wide variety of data sets to draw practical conclusions. In fact, Big Data, much like truckloads of bricks or bags of cement, isn’t useful on its own, it’s what you do with it that counts.

Kost Materials y Tecnologías Sysdyne: Rompiendo el molde cliente – vendedor

Un estudio de caso de Kost materials: una asociación impulsada por la tecnología y el servicio al cliente

Kost Materials ha crecido de una planta, 12 camiones y 15 empleados en 2013 a 5 plantas de concreto premezclado, 80 camiones, 90 empleados y sus propias terminales de almacenamiento de cemento y cenizas en 2021 con Sysdyne.

“

ConcreteGO nos dio la capacidad de hacer estas cosas nosotros mismos y todo fue parte de nuestra asequible suscripción anual. Se acabó la firma de contratos adicionales y el tiempo de inactividad al agregar activos.”

– Mandi Yurecko, gerente general de Kost Materials

En los primeros años, Kost Materials se dio cuenta rápidamente de la necesidad de un programa de despacho para seguir su tendencia de crecimiento. Una vez que supieron sobre Sysdyne y su programa de despacho ConcreteGO, fueron vendidos. El factor principal que ayudó en su decisión fue la reducción en varias tarifas que habían estado experimentando con su programa anterior. Cada vez que necesitaran agregar un camión o usuario adicional, habría tarifas asociadas con cada artículo y tendrían que depender de un miembro de soporte para realizar estas adiciones.

“

iStrada nos ha ayudado a ser más eficientes y oportunos cuando se trata de despachar pedidos de concreto.”

– Mandi Yurecko, gerente general de Kost Materials

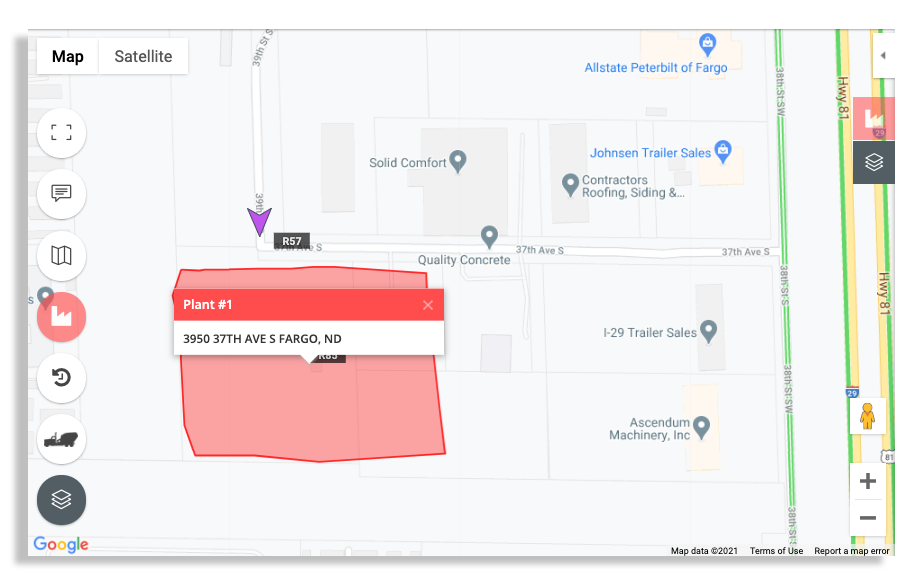

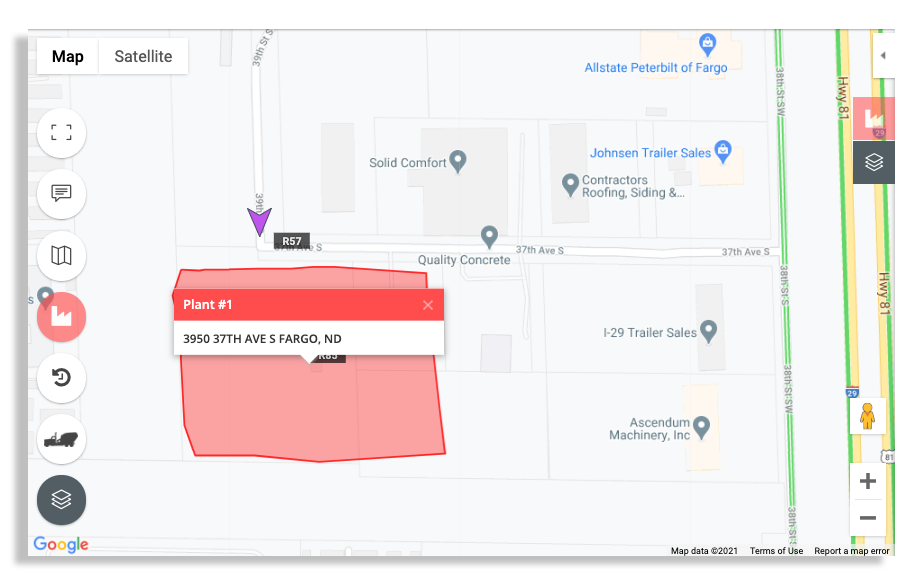

Recientemente, Kost Materials también ha agregado a su arsenal el rastreo de camiones GPS iStrada de Sysdyne. Con sus plantas y camiones tan dispersos, se estaba volviendo más desafiante para ellos controlar tantas partes móviles y utilizar sus activos lo mejor que podían.

|

“Las funciones de geocercas y estado automático han ayudado a reducir las conversaciones de radio y los constantes intercambios entre los conductores y el despacho. ConcreteGO e iStrada definitivamente han ayudado a optimizar nuestros procesos de envío y GPS.”

– Mandi Yurecko, gerente general de Kost Materials

|

Kost Materials destacó su agradecimiento por los miembros del equipo de ventas, soporte y tecnología de Sysdyne: cada vez que necesitan algo, están allí para ayudar y ofrecer soluciones. La capacidad de obtener ayuda casi instantáneamente está más allá de las palabras. Con su programa anterior, tomaría horas llegar al soporte y era un juego de espera constante.

“¡Sysdyne siempre se apresura a reconocer nuestras necesidades y nos asegura que hay alguien!”

– Mandi Yurecko, gerente general de Kost Materials

Kost Materials se da cuenta de que se están produciendo cambios en la industria en lo que respecta a la tecnología, y aprecia ver a Sysdyne moverse con ella y agregar funciones.

Sysdyne Technologies es una innovadora empresa de desarrollo de software con sede en Stamford, CT. La compañía ha estado transformando la industria del concreto premezclado durante más de 40 años mediante el diseño y la comercialización de una nueva tecnología innovadora de gestión de lotes, despacho y entrega basada en la nube y ofreciendo el mejor servicio al cliente para permitir que los clientes trabajen de manera más eficiente, más rentable y para facilitar su trabajo.