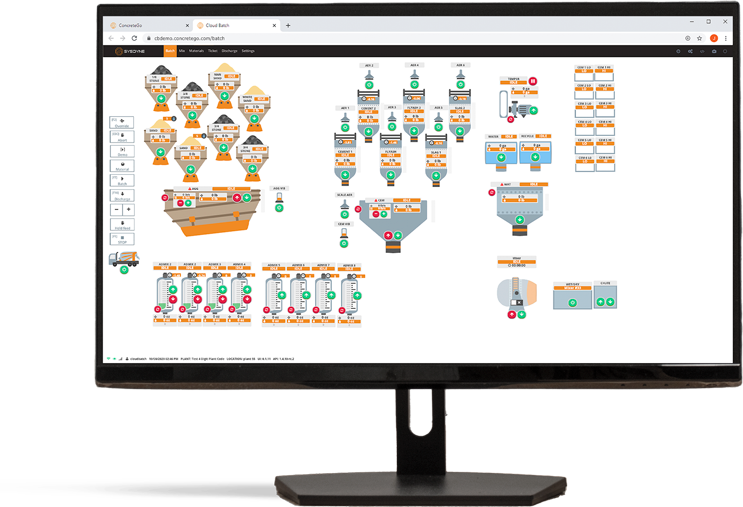

CloudBatch™: The World’s First and Only Cloud-Native Batch Control System in the Concrete Industry

Controlling the concrete batching process in real-time from anywhere, at any time, creates tremendous value and reduces operational costs. Users can simply log in through their browser on any device and operating system to monitor and adjust any load of concrete easily and securely. This disruptive batch system revolutionizes concrete production, offering advanced features and seamless accessibility. With CloudBatch, users can experience uninterrupted operation, real-time visibility, and simplified management of multiple batch jobs.

Reimagine the Batching Process

Access Anytime, Anywhere

CloudBatch provides access to the batching system from any location and at any time, offering unparalleled flexibility and convenience. You can batch concrete anywhere using a PC, laptop, or tablet by logging in to your Sysdyne account.

Single Source of Truth

Multiple users can access a single database to manage dispatch and batch operations simultaneously. Concerned about the inconsistency between batch and dispatch information? Now you can manage mixes, constituents, customers, projects, orders, and tickets all in one place.

Money Savings

Save material costs by allowing managers to closely monitor the batch process and material usage and make prompt adjustments to save materials without interfering with the loading cycle. Concrete producers can save $0.21 to $0.42 per yard per year on cement consumption with CloudBatch.

CloudBatch Features

Sysdyne’s CloudBatch platform is designed and developed as an integral part of Sysdyne’s ConcreteGO® Cloud dispatch. The technology helps speed up the batch process and reduce costs by tightly controlling material usage. Its capabilities offer unprecedented accessibility, connectivity, and visibility for the concrete industry.

Easy Access for Multiple Users

Real-Time Inventory

Offline Mode

Predictive Maintenance

PAC System

Replay Previous Loads

OpenAI

Local Ticket Sync

“CloudBatch has revolutionized the way we manage our batching process. The ability to monitor and adjust loads in real-time from any device has significantly reduced our operational costs and improved our production efficiency. It's like having the entire plant at my fingertips, no matter where I am.”

Quality Control Manager at UrbanCrete Solutions

“Since integrating CloudBatch, we've seen a dramatic improvement in our inventory management. The real-time inventory tracking feature ensures we always know our material usage, which helps us reduce waste and optimize our supply chain. The unified database has also made our dispatch and batching operations more consistent and reliable.”

Operations Director at BuildWell Construction

"CloudBatch's predictive maintenance and remote update capabilities have been game-changers for us. We no longer need to send staff on long trips for maintenance checks or software upgrades. This system has not only cut down on our downtime but also allowed us to save on unnecessary maintenance costs. The replay feature is incredibly useful for analyzing and improving our batching processes.”

Plant Manager at ReadyMix Concrete Inc.

CLOUD•BATCH FAQs

What if I lose internet connection?

How does CloudBatch control the concrete plant?

Can I batch remotely?

Can I have my batch man load concrete using a tablet?

Do I have to have ConcreteGO to use CloudBatch?

Can I upgrade my current Pioneer batch control to CloudBatch?

Is CloudBatch more expensive?

There is no upfront cost to purchase the CloudBatch cloud native batch system. Sysdyne offers a simple monthly subscription model that excludes shipping, handling, and installation charges. There are no annual maintenance fees if Sysdyne installs the system or if you choose the monthly subscription. Please contact a Sysdyne sales representative for more information sales@sysdynetechnologies.com.

How does the unified database between dispatch and batch work?

Can I see other plants?

How long is my data saved?

What type of maintenance is required for CloudBatch?

REQUEST YOUR FREE DEMO TODAY!

EXPLORE SYSDYNE’S SUITE OF PRODUCTS

Our fully integrated products cover the entire spectrum of concrete operations; from sales, to production, to delivery management and billing. The innovative dispatch, batch control, delivery tracking, paperless ticketing, and customer collaboration platform, help concrete producers worldwide run more efficiently and profitably.