The fastest path to smarter concrete operations

Because every

minute matters.

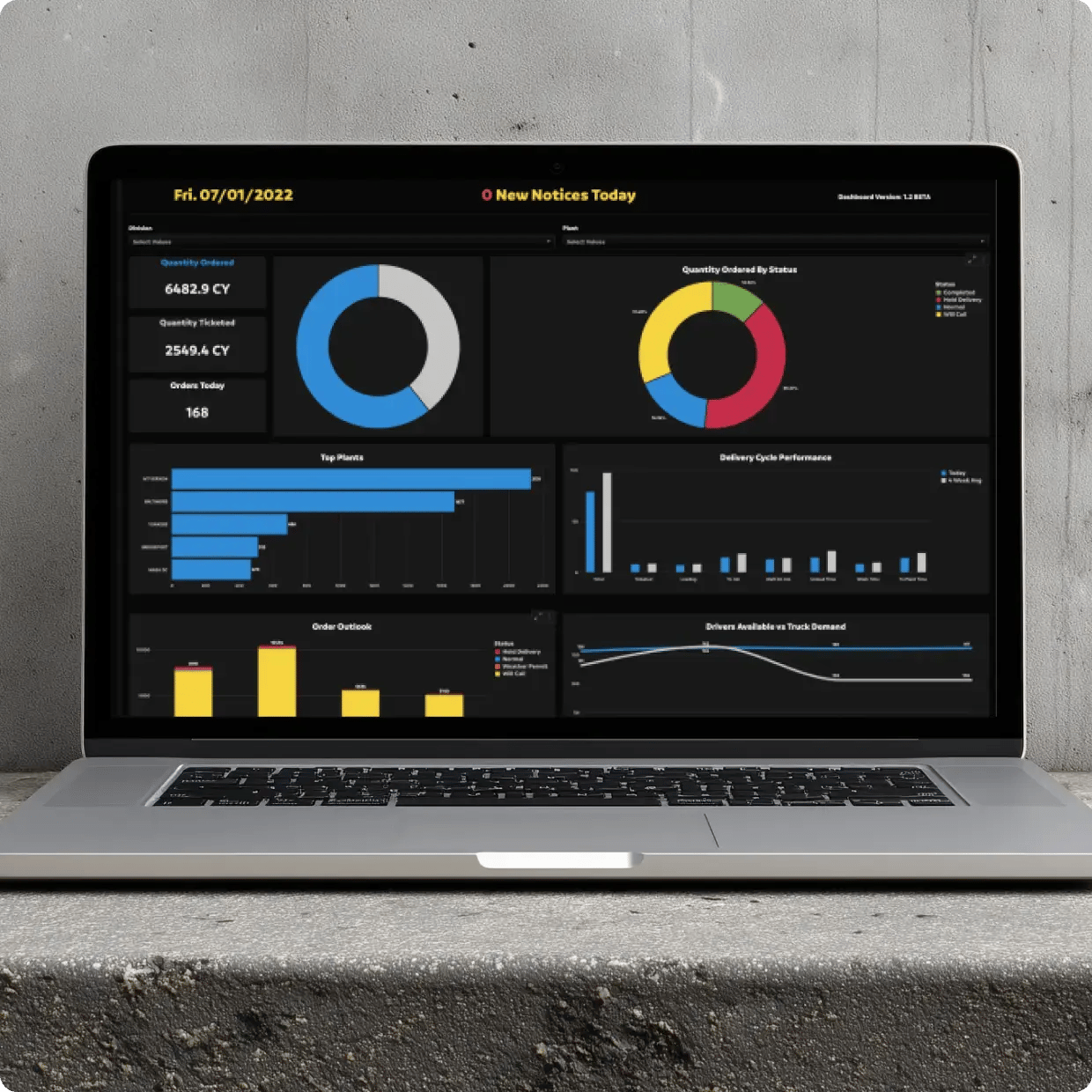

Modern tools. Proven results. Sysdyne helps ready-mix producers pour more concrete, make more money, and spend less time doing it.

Maximize revenue.

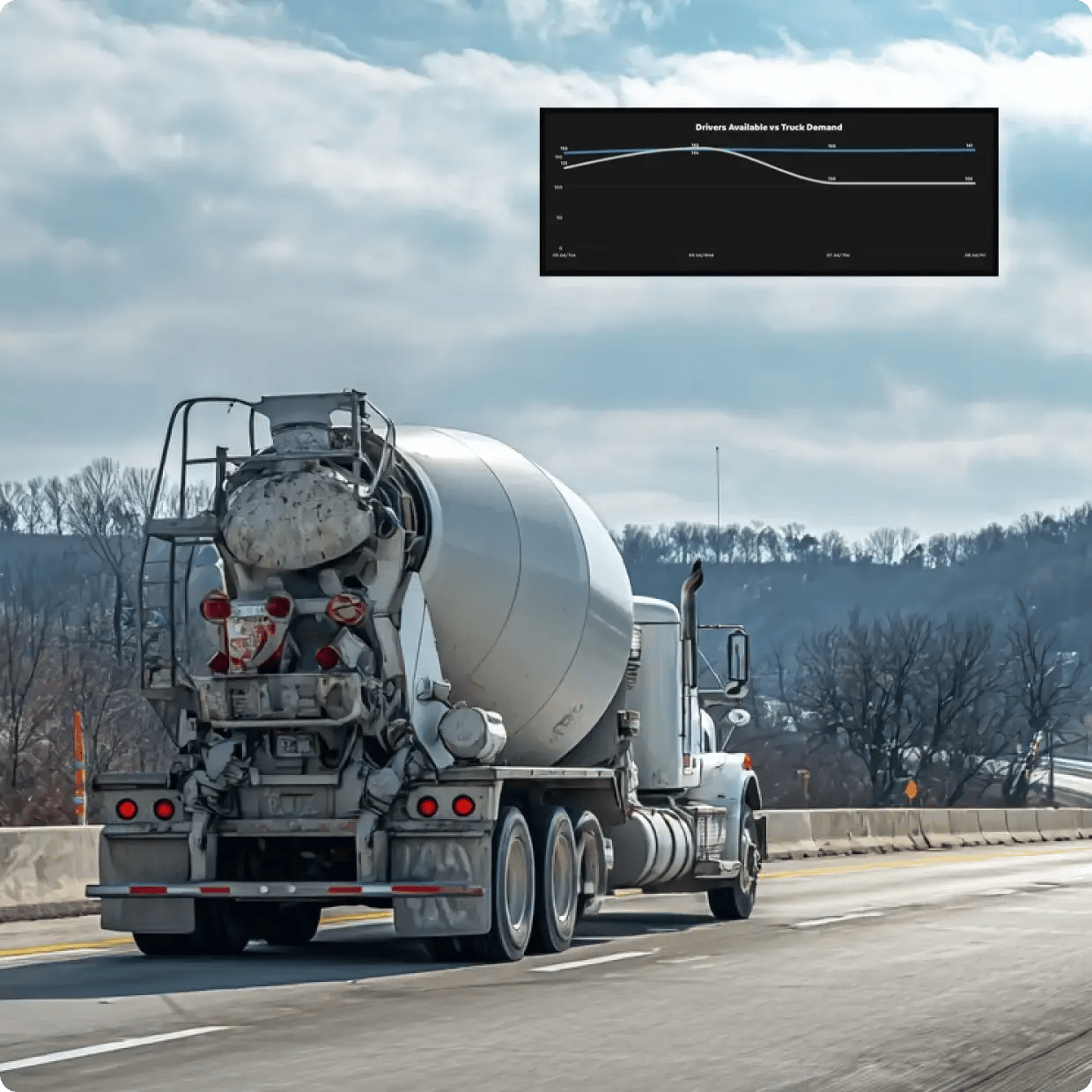

Tight margins and tighter timelines make every truck minute count. Sysdyne helps you capture more loads per day, reduce waste, and turn insight into income.

Pour more concrete,

make more money.

-

Faster load turnaround

Up to 50% faster with real-time visibility and automation.

-

Built in intelligence

Business intelligence to reduce waste and identify revenue leaks

-

Interoperable platform

Ensures your systems are always connected, never clunky.

-

Tools that scale

Grow across plants, customers, and regions—without scaling complexity.

Simplify operations.

The days of managing disjointed legacy systems are over. Sysdyne’s fully integrated, modular platform makes complexity disappear and onboarding frictionless.

Everything just works—together

-

Cloud native

Architecture that’s stable, scalable, and secure.

-

Intuitive UI

Enables new employees to ramp quickly, no training manuals required.

-

Zero-maintenance

Updates keep you modern with constant product releases

-

Flexible APIs

Modular design ensure your tech stack evolves with your business.

Save time.

From instant implementation to hands-on support, Sysdyne is built for speed at every step of the journey. You’ll be up and running in days—not months—and saving time every day after.

Every minute matters—we help you get more.

-

Go live

Live in hours/days, not weeks/months.

-

Embedded automation

Cutting out manual steps across dispatch, billing, and delivery.

-

Instant support

Responses in minutes, not tickets that linger for days.

-

Rapid ROI

Most customers see measurable value in just weeks.

Drive profitability and efficiency

The industry’s only full cycle, cloud native platform.

Trusted by over 300 producers—and growing at 50% year-over-year—our tools streamline every stage of your operation. From dispatch to delivery, we eliminate the noise, so you can focus on what really matters: moving more concrete, faster.