Better mixes start with

better tracking.

Take control of concrete quality with a tamper-proof mixing counter built for precision.

02

Approvals: NYSDOT & NJSDOT

<01

Amp power draw

0.44”

Bright LED lights

Five simple reasons MRC Pro matters for mixing.

-

Approved for state jobs

NYSDOT and NJSDOT approved—required for critical projects.

-

Total visibility

See mixing and total revolutions, RPM, and mix time—live and accurate.

-

No room for tampering

Reset requires a cable—no accidental or unauthorized changes.

-

Installs fast

Includes mounting plate, harness, and pickup bracket for a plug-and-play install.

-

Built for the field

Compact, rugged, and water-resistant—made to last on the jobsite.

Purpose-built for ready-mix

Platform Overview

Ultra-Bright LED Display

Large digits remain crystal clear in direct sunlight or low light.

Dual Display Modes

Toggle between drum RPMs and total mix time since reset.

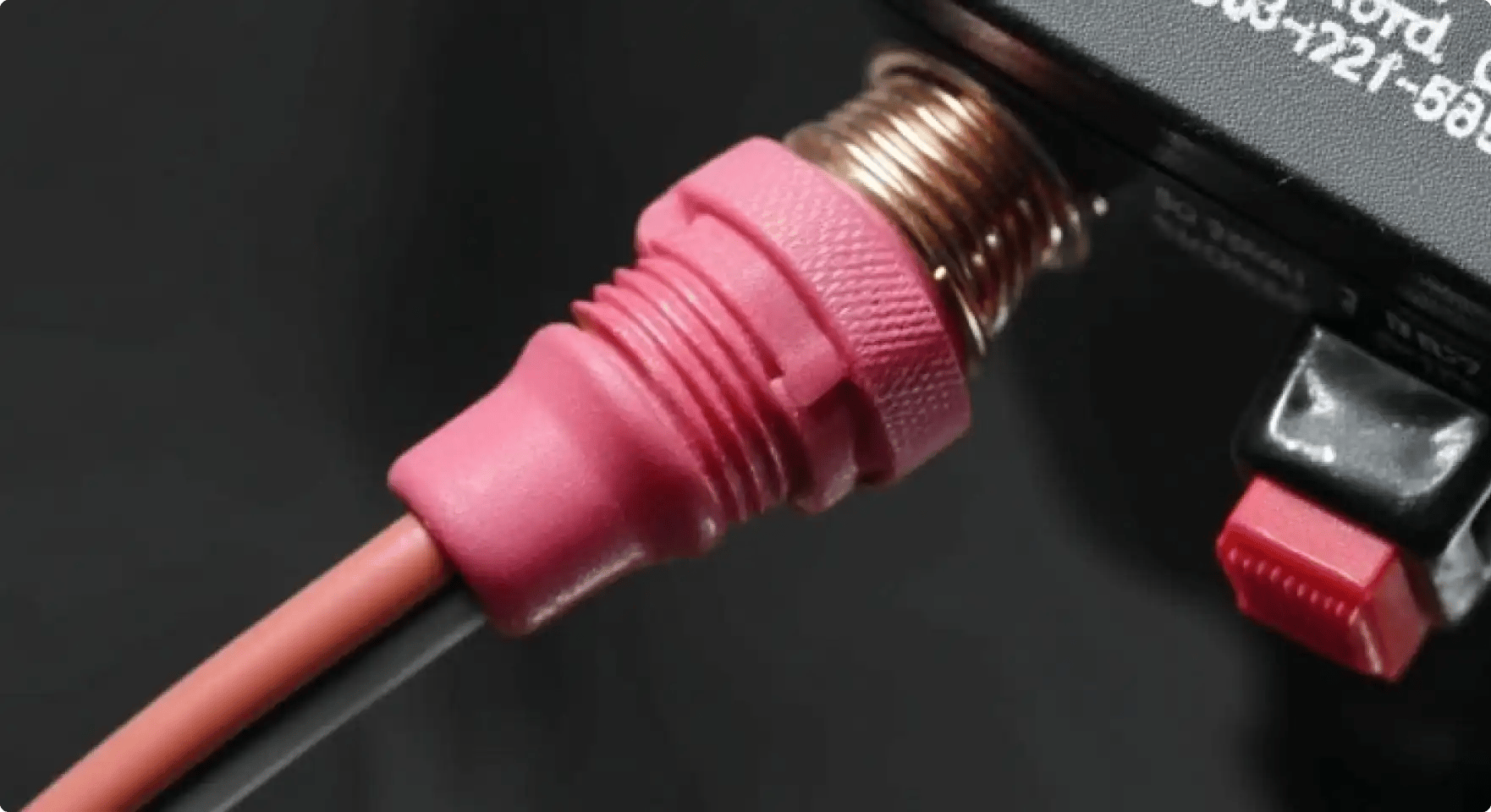

Reset Protection

Tamper-proof interlock and recessed connector avoid accidental resets.

Low Power. High Efficiency.

Draws less than 1 amp, saving energy without sacrificing performance.

Flexible Compatibility

Works with proximity switches, limit switches, and existing harnesses.

Take their word for it.

Customer Stories“With the reliability of Sysdyne’s solutions, we can provide better products and on-time service, day in and day out. That’s what our customers want and ultimately why they choose to do business with a ready-mix company like us”

TJ Oneglia, O&G Industries

Track your mix. Protect your quality.

The Sysdyne MRC-Pro Mixing Revolution Counter is purpose-built for ready-mix producers who need fast installs, DOT approval, and peace of mind—at a price that works.