Fully automated truck status updates.

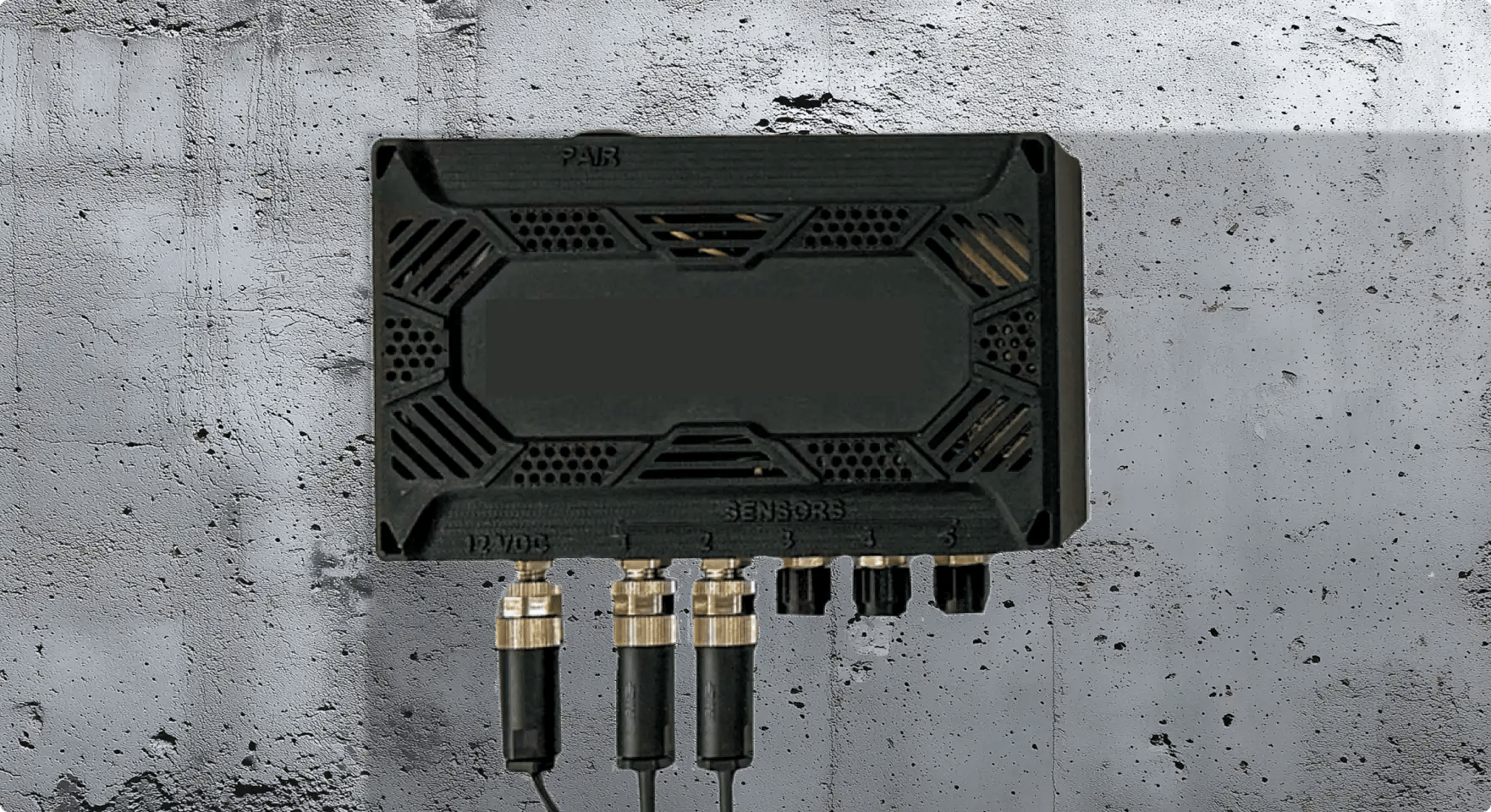

The DeliveryGo Sensor eliminates manual inputs and delivers real-time fleet visibility—maximizing efficiency and delivery accuracy.

100%

Automated status updates

0

Manual input required from drivers

01

System for total fleet visibility

Five simple reasons DeliveryGo Sensor matters for dispatch.

-

End Manual Entry

No more driver updates—statuses are tracked and sent automatically.

-

Speed Up Deliveries

Improved dispatching and turnaround times increase truck utilization.

-

Boost Mix Quality

Track drum speed and direction to ensure consistent concrete on every load.

-

Make Smarter Decisions

Real-time insights let you monitor job, driver, and customer performance.

-

Drive ROI Fast

Get value quickly with easy install, seamless software integration, and labor savings.

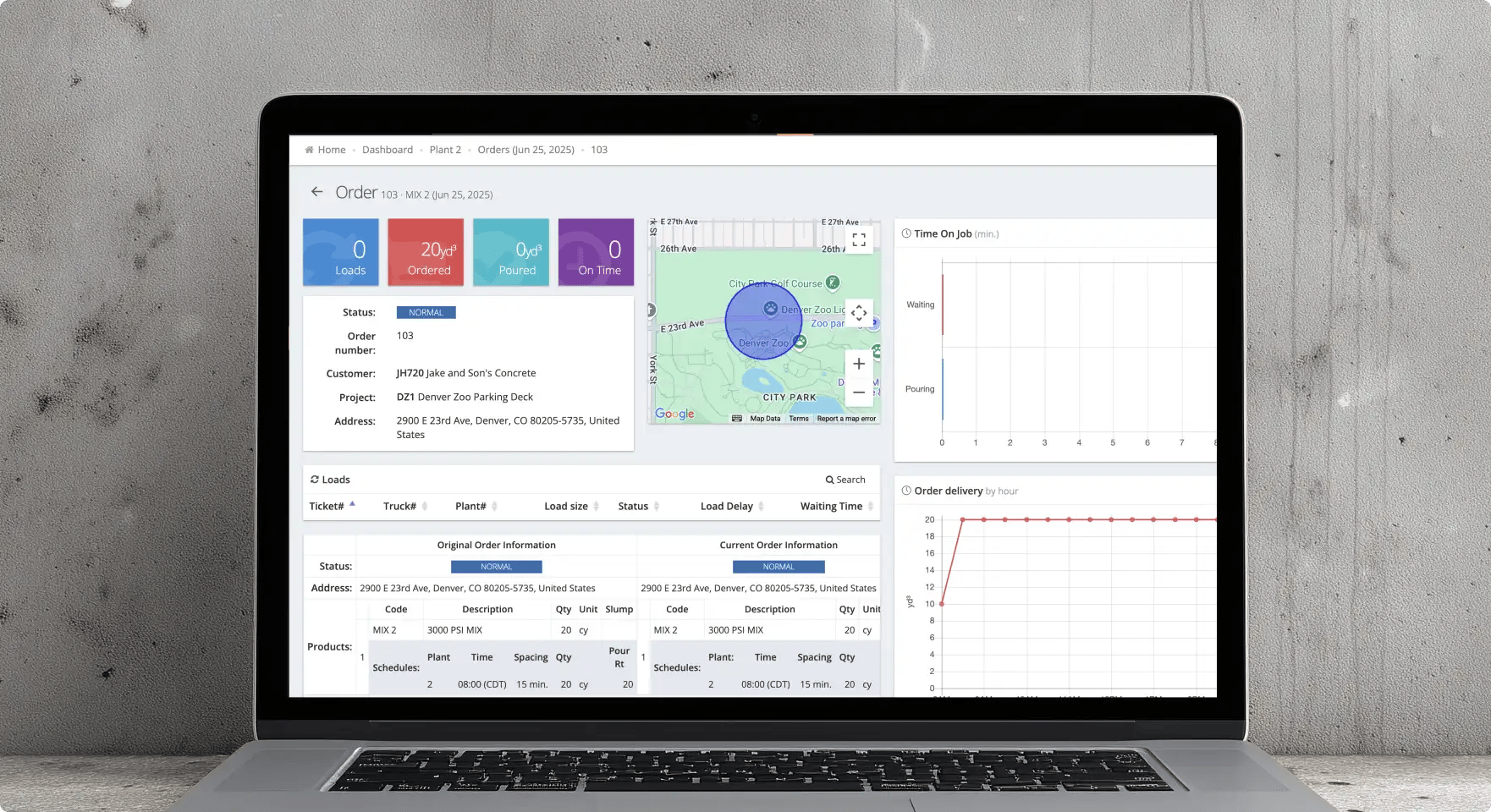

Total team visibility

Platform Overview

Automated Truck Status Updates

From ticketed to pour to wash, updates are handled in real time—no driver action needed.

Advanced Drum Rotation Detection

Monitors drum speed, direction, and RPM for quality assurance and performance tracking.

Accurate Water Recording

Connects to the truck’s water meter to log exact water quantities added at the plant and on-site.

Seamless iStrada Integration

Built in-house to pair perfectly with Sysdyne’s cloud-native ticketing and dispatch tools.

Quick Bluetooth Setup

Installs easily and pairs with driver tablets for real-time data flow powered by the truck battery.

Take their word for it.

Customer Stories“The geofence and auto-status features have helped cut down radio chatter and back-and-forth between drivers and dispatch. ConcreteGo and DeliveryGo have helped streamline our dispatch and GPS processes.”

Mandi Yureko, Kost Materials

Take the guesswork out of delivery.

The DeliveryGo Sensor gives your dispatch team total visibility while saving your drivers time and reducing costly errors. Fully integrated, fully automated—and fully ready to grow your bottom line.