BATCH CONTROL. SIMPLIFIED.

The world’s 1st Cloud-Native batch control system, setting a new standard in excellence.

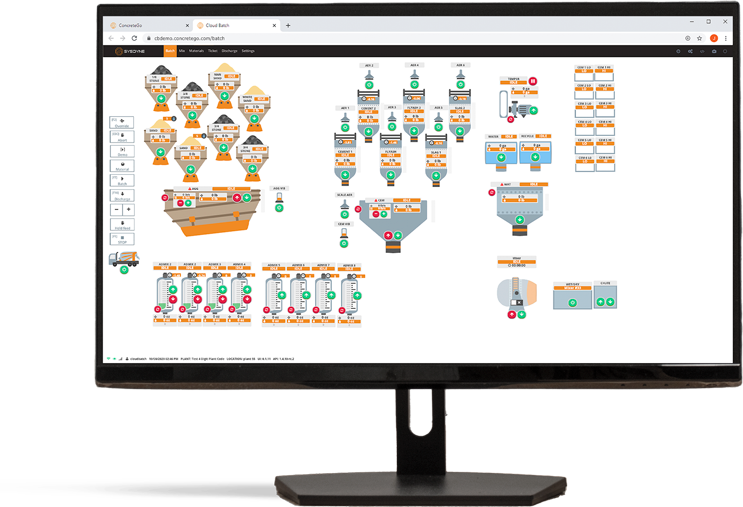

The enhanced ability to control the concrete batching process in real-time from anywhere at anytime creates tremendous value and savings. Users can simply log in through their browser on any device to monitor and adjust any load of concrete easily and securely.

WHAT ARE THE BENEFITS OF CLOUD•BATCH?

Access Anytime, Anywhere

Simply log in to your Sysdyne ID account. Want to save costs with a low-production plant? CloudBatch is the answer. You can batch concrete anywhere using a PC, laptop, or tablet.

Single Source of Truth

Use a single database to manage dispatch and batch operations Concerned about the inconsistency between batch and dispatch information? Now you can manage mixes, constituents, customers, projects, orders, and tickets all in one place. Want to incorporate batch data into your business analysis reports? CloudBatch is the answer with its new powerful production database

Open API

Concerned about connecting batch controls to external ERP systems such as SAP? CloudBatch’s OpenAPI allows full data exchanges without the limitation of the traditional batch interface.

Real Time Inventory

Looking for a solution to track inventory in real-time? Inventory is automatically updated as batch operators record material receipts and load concrete.

Money Savings

Save material costs by allowing managers to closely monitor the batch process and material usage and make prompt adjustments to save materials without interfering with the loading cycle. Is it too much to drive around making mix design changes? Now QC staff can review mix designs and make adjustment remotely

Predictive Maintenance

Notify plant managers when maintenance is due to avoid plant shutdowns and avoid unnecessary maintenance costs. Is it too much to drive 100 miles to do a batch program upgrade? No longer needed, Sysdyne will automatically update new versions as they become available.

Replay Previous Loads

Want to find out exactly what happened with a load? Using the replay feature with CloudBatch™, you can download up to 7 mins video. This solution provides predictive maintenance to lower downtime, and a unified database (dispatch and batching) to power advanced analytics for decision-makers, all at your fingertips.

CLOUD•BATCH FEATURES

Sysdyne’s revolutionary CloudBatch™ is designed and developed as an integral part of Sysdyne’s ConcreteGO® Cloud dispatch. It provides unprecedented accessibility, connectivity, and visibility.

EASY ACCESS USING ANY INTERNET ENABLED DEVICE

REAL-TIME INVENTORY

PREDICTIVE MAINTENANCE

UNIFIED DATABASE

OPENAPI

“ConcreteGO® and iStrada® have allowed us to change the way we do business and become industry leaders with paperless systems and customer interaction.”

Elvin Group

“ConcreteGO® and iStrada® have allowed us to change the way we do business and become industry leaders with paperless systems and customer interaction.”

Elvin Group

“ConcreteGO® and iStrada® have allowed us to change the way we do business and become industry leaders with paperless systems and customer interaction.”

Elvin Group

CLOUD•BATCH FAQs

What if I lose internet connection?

How does CloudBatch control the concrete plant?

Can I batch remotely?

Can I have my batch man load concrete using a tablet?

Do I have to have ConcreteGO to use CloudBatch?

Can I upgrade my current Pioneer batch control to CloudBatch?

Is CloudBatch more expensive?

How does the unified database between dispatch and batch work?

Can I see other plants?

How long is my data saved?

What type of maintenance is required for CloudBatch?

REQUEST YOUR FREE DEMO TODAY!

EXPLORE SYSDYNE’S SUITE OF PRODUCTS

Our fully integrated products cover the entire spectrum of concrete operations; from sales, to production, to delivery management and billing. The innovative dispatch, batch control, delivery tracking, paperless ticketing, and customer collaboration platform, help concrete producers worldwide run more efficiently and profitably.