How Networking Plants Using ConcreteGO CloudBatch™ Benefit Concrete Producers

Maximo Ares Garcia has been working in the construction industry for over 7 years. He began as a sales consultant for concrete equipment with a variety of concrete companies in Latin America. He was responsible for helping and guiding them to maximize plant production output from their equipment and getting the best return on investment. Maximo knows concrete batch equipment, and in his opinion, the new CloudBatch from Sysdyne is changing the way we batch concrete. What is the real value of CloudBatch for Concrete producers, especially those with plants in rural areas?

Traditionally to perform batch plant maintenance and system upgrades, resources are dispatched to go onsite to each individual plant, costing man hours and a loss in production revenue. For producers with plants in rural areas, this is especially a problem. It forces the plant to shut down and production to stop which cost money, not to mention the cost of sending people for the day or in some cases several days to install, troubleshoot and test new batch software updates.

What is the real value of CloudBatch for Concrete producers, especially those with plants in rural areas?

Traditionally to perform batch plant maintenance and system upgrades, resources are dispatched to go onsite to each individual plant, costing man hours and a loss in production revenue. For producers with plants in rural areas, this is especially a problem. It forces the plant to shut down and production to stop which cost money, not to mention the cost of sending people for the day or in some cases several days to install, troubleshoot and test new batch software updates.

La innovación impulsa la eficiencia y la rentabilidad

Un estudio de caso de CowTown Redi Mix

Parte 1: Proceso de facturación simplificado

– Les Hogan, director general de CowTown Redi Mix

La historia de CowTown es de innovación e inspiración: a partir de 2002 con una pequeña flota de mezcladoras y una planta de concreto, CowTown se ha convertido en un jugador regional feroz con más de 150 camiones de concreto premezclado y seis plantas de concreto que prestan servicios en el área de Dallas / Fort Worth.

Los propietarios de CowTown tienen un buen ojo para las nuevas oportunidades comerciales y saben cómo aprovechar el software en la nube para acelerar su crecimiento. CowTown fue uno de los primeros en adoptar el ConcreteGO Cloud Dispatch de Sysdyne, lo que les permitió minimizar la necesidad de construir y soportar una compleja infraestructura de TI interna, lo que a su vez ahorró costos y recursos. Agregar plantas al despacho de ConcreteGO es tan simple como unos pocos clics: después de implementar con éxito ConcreteGO, CowTown decidió seguir adelante e instalar Sysdyne Batch Controls en sus plantas.

A medida que crecían, CowTown enfrentó desafíos comunes en la industria del concreto: agilizar el proceso de facturación y reducir el costo y los días de cobranza de cuentas por cobrar. Antes de implementar la solución de Sysdyne, los mensajeros conducían a cada planta y recolectaban boletos de papel a diario. Regresarían a la oficina principal con montones de boletos que luego fueron escaneados, archivados y finalmente archivados en cajas. El personal administrativo dedicó una gran cantidad de tiempo a clasificar el papel para asociar los tickets con las facturas adecuadas. Luego, los boletos se escanearon individualmente, se adjuntaron a facturas separadas y se enviaron a los clientes. Todo el proceso fue costoso, lento, ineficiente y propenso a errores.

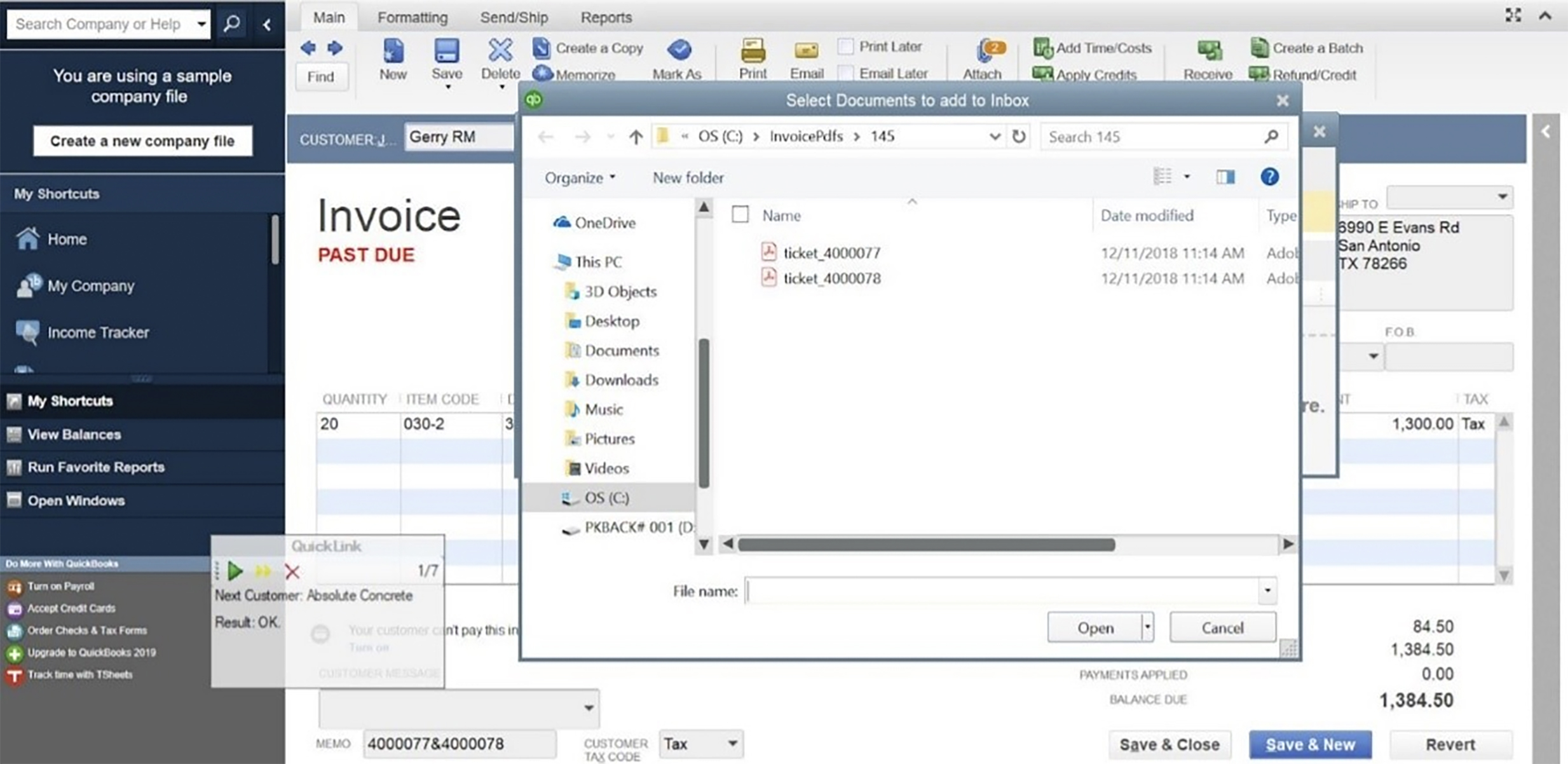

CowTown se acercó a Sysdyne en busca de una solución. En 2019, CowTown comenzó a implementar iStrada de Sysdyne, una solución de rastreo de camiones GPS con todas las funciones que incluye emisión de boletos sin papel, cronometraje, plataformas de colaboración entre contratistas e inspectores, paneles de control de KPI (indicadores clave de rendimiento) y la herramienta de integración ERP bidireccional de Sysdyne, Quicklink. Con la emisión de boletos sin papel de iStrada, todos los boletos finales recolectados por los conductores se almacenan en un lugar seguro en formato PDF. El nuevo proceso hizo que el personal administrativo usara Quicklink para abrir tickets de ConcreteGO y crear una factura en su programa de facturación descargando el ticket PDF de iStrada y guardándolo en una carpeta local en su computadora. Luego, harían clic en el botón adjuntar archivo en su programa de facturación y navegarían por las carpetas de la computadora identificadas por el número de factura para encontrar los tickets en PDF y adjuntarlos a la factura. Vea el diagrama a continuación:

“Lo que solía llevarnos más de cuatro horas, ahora nos lleva menos de 15 minutos.”

“Lo que solía llevarnos más de cuatro horas, ahora nos lleva menos de 15 minutos.”– Les Hogan, director general de CowTown Redi Mix

Sysdyne ha sido el socio tecnológico de CowTown en cada paso del camino. El siguiente paso en el viaje de CowTown hacia la transformación digital es implementar un proceso basado en códigos QR que vincule el cronometraje con la nómina. El flujo de trabajo se desarrolló con Sysdyne y agilizará significativamente el proceso de entrada / salida de los empleados y mejorará la nómina. Esperamos continuar nuestra larga y exitosa relación con nuestros socios en CowTown y saludamos el espíritu innovador que les sirve a medida que continúan creciendo y prosperando.

– Sam Shmaisani, director ejecutivo de CowTown Redi Mix.