Digital Collaboration: An Integral Part of the Concrete Delivery Ecosystem

Best practices can be shared collectively across a variety of different industries. Over the last year, many businesses have had to adapt to a more hybrid approach to working remotely and learn how to work more effectively and efficiently. As a result, Ready-Mix Concrete producers have found that using digital collaboration platforms like iStrada have dramatically improved the way project stakeholders exchange and communicate with each other within the concrete delivery ecosystem. Ready-Mix suppliers are quickly finding out that some of these new digital workflows have positive benefits beyond employee health and safety during the pandemic, including strong returns on investment such as reducing costly delays and creating more efficient data workflows using better communication tools. The major trend in the Concrete industry is the digital transformation of batch, dispatch and concrete delivery management powered by the cloud and online collaboration platforms. Endless numbers of exchanges between dispatchers, contractors and DOT inspectors can be handled by simply logging into Sysdyne’s iStrada App to visualize concrete delivery status and performance data as it happens. Stakeholders can download digital copies of the tickets and inspection reports anytime, anywhere using any mobile device. The enhanced ability to share information from a central online location cuts down on miscommunications and promotes more efficient ways of being able to act on information throughout the day. Due to the heavy demands on Ready Mix Suppliers to manage and anticipate order delivery times, the use of integrated collaboration platforms like iStrada have been helping improve the delivery process for all stakeholders by making data more easily accessible.

The major trend in the Concrete industry is the digital transformation of batch, dispatch and concrete delivery management powered by the cloud and online collaboration platforms. Endless numbers of exchanges between dispatchers, contractors and DOT inspectors can be handled by simply logging into Sysdyne’s iStrada App to visualize concrete delivery status and performance data as it happens. Stakeholders can download digital copies of the tickets and inspection reports anytime, anywhere using any mobile device. The enhanced ability to share information from a central online location cuts down on miscommunications and promotes more efficient ways of being able to act on information throughout the day. Due to the heavy demands on Ready Mix Suppliers to manage and anticipate order delivery times, the use of integrated collaboration platforms like iStrada have been helping improve the delivery process for all stakeholders by making data more easily accessible.

La innovación impulsa la eficiencia y la rentabilidad

Un estudio de caso de CowTown Redi Mix

Parte 1: Proceso de facturación simplificado

– Les Hogan, director general de CowTown Redi Mix

La historia de CowTown es de innovación e inspiración: a partir de 2002 con una pequeña flota de mezcladoras y una planta de concreto, CowTown se ha convertido en un jugador regional feroz con más de 150 camiones de concreto premezclado y seis plantas de concreto que prestan servicios en el área de Dallas / Fort Worth.

Los propietarios de CowTown tienen un buen ojo para las nuevas oportunidades comerciales y saben cómo aprovechar el software en la nube para acelerar su crecimiento. CowTown fue uno de los primeros en adoptar el ConcreteGO Cloud Dispatch de Sysdyne, lo que les permitió minimizar la necesidad de construir y soportar una compleja infraestructura de TI interna, lo que a su vez ahorró costos y recursos. Agregar plantas al despacho de ConcreteGO es tan simple como unos pocos clics: después de implementar con éxito ConcreteGO, CowTown decidió seguir adelante e instalar Sysdyne Batch Controls en sus plantas.

A medida que crecían, CowTown enfrentó desafíos comunes en la industria del concreto: agilizar el proceso de facturación y reducir el costo y los días de cobranza de cuentas por cobrar. Antes de implementar la solución de Sysdyne, los mensajeros conducían a cada planta y recolectaban boletos de papel a diario. Regresarían a la oficina principal con montones de boletos que luego fueron escaneados, archivados y finalmente archivados en cajas. El personal administrativo dedicó una gran cantidad de tiempo a clasificar el papel para asociar los tickets con las facturas adecuadas. Luego, los boletos se escanearon individualmente, se adjuntaron a facturas separadas y se enviaron a los clientes. Todo el proceso fue costoso, lento, ineficiente y propenso a errores.

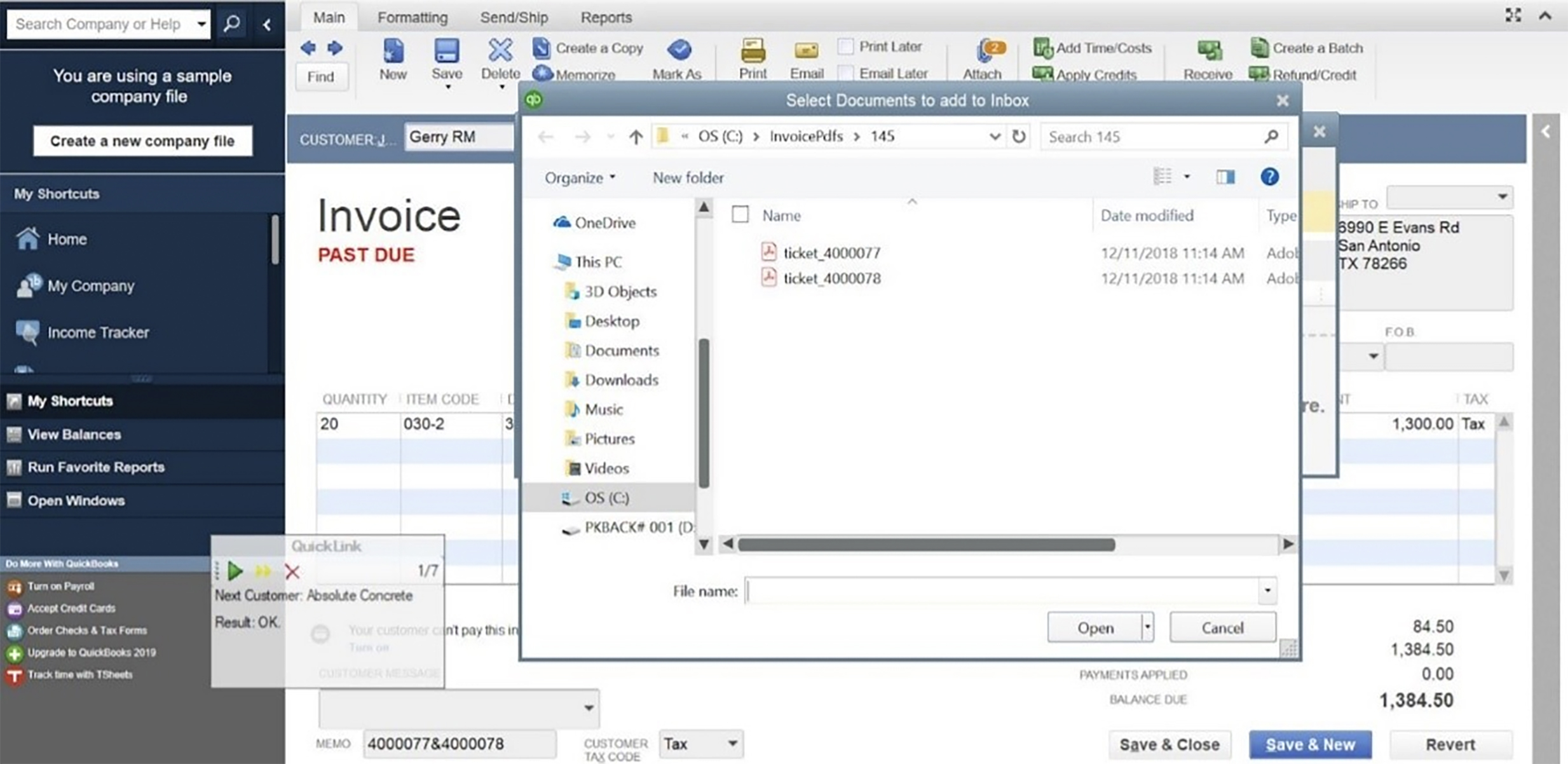

CowTown se acercó a Sysdyne en busca de una solución. En 2019, CowTown comenzó a implementar iStrada de Sysdyne, una solución de rastreo de camiones GPS con todas las funciones que incluye emisión de boletos sin papel, cronometraje, plataformas de colaboración entre contratistas e inspectores, paneles de control de KPI (indicadores clave de rendimiento) y la herramienta de integración ERP bidireccional de Sysdyne, Quicklink. Con la emisión de boletos sin papel de iStrada, todos los boletos finales recolectados por los conductores se almacenan en un lugar seguro en formato PDF. El nuevo proceso hizo que el personal administrativo usara Quicklink para abrir tickets de ConcreteGO y crear una factura en su programa de facturación descargando el ticket PDF de iStrada y guardándolo en una carpeta local en su computadora. Luego, harían clic en el botón adjuntar archivo en su programa de facturación y navegarían por las carpetas de la computadora identificadas por el número de factura para encontrar los tickets en PDF y adjuntarlos a la factura. Vea el diagrama a continuación:

“Lo que solía llevarnos más de cuatro horas, ahora nos lleva menos de 15 minutos.”

“Lo que solía llevarnos más de cuatro horas, ahora nos lleva menos de 15 minutos.”– Les Hogan, director general de CowTown Redi Mix

Sysdyne ha sido el socio tecnológico de CowTown en cada paso del camino. El siguiente paso en el viaje de CowTown hacia la transformación digital es implementar un proceso basado en códigos QR que vincule el cronometraje con la nómina. El flujo de trabajo se desarrolló con Sysdyne y agilizará significativamente el proceso de entrada / salida de los empleados y mejorará la nómina. Esperamos continuar nuestra larga y exitosa relación con nuestros socios en CowTown y saludamos el espíritu innovador que les sirve a medida que continúan creciendo y prosperando.

– Sam Shmaisani, director ejecutivo de CowTown Redi Mix.