Cloud Batching Solutions for Concrete Industry Success

BATCH CONTROL. ANYWHERE. ANY TIME.

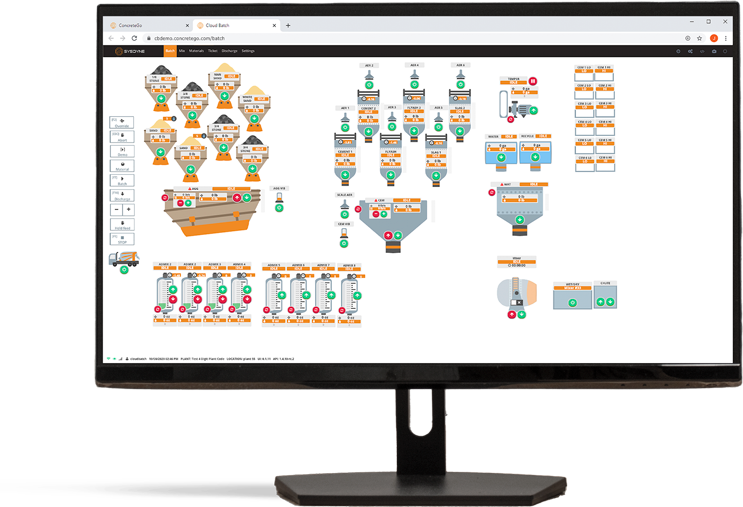

Sysdyne simplifies central batching, reducing labor requirements. A single batch operator can oversee multiple plants, enhancing productivity and efficiency. Our core batching products, ConcreteGO and CloudBatch, share a single database, offering real-time data for better coordination and reduced duplication in scheduling and dispatch. The ability to access batch processes, data, and more using a browser to closely monitor and make adjustments at the plant in real-time, as it happens, creates tremendous value and savings. Utilizing compute resources for dynamic resource provisioning ensures efficient management of batch control processes, allowing organizations to scale efficiently without manual intervention.

Advantages of Our Batch Processing Systems

- Uninterrupted Batching: CloudBatch ensures continuous concrete batching even if the batch computer is down, reducing downtime and boosting productivity.

- Real-Time Inventory Updates: CloudBatch provides real-time updates on inventory, allowing precise monitoring of material availability.

- Offline Mode: Seamless transition to offline mode ensures uninterrupted operation without an internet connection.

- PAC System: CloudBatch uses a Programmable Automation Controller (PAC) for advanced performance and robust control tasks.

- Replay: Users can replay batching processes to review and optimize previous batch operations.

- Local Ticket Sync: Sync offline-batched tickets with ConcreteGo to maintain seamless data integration during internet outages.

Core Business Intelligence and Data Integration Solutions

Related Products for Batch Jobs

"CloudBatch continues to improve and gain new features constantly, and I look forward to continuing our partnership with Sysdyne."

Croell, Inc.

“People want to be able to access information at any time and from anywhere, why should concrete batch software be any different?”

Loveland Ready Mix

"...with the cloud capabilities, we can make sure we’re not over or under batching certain products, and can adjust mix designs & quantities. End of day, we run reports and see how many tons of cement and stone were used at each plant, then share that information with our back office for accounting purposes."

O&G Industries

Batch Processing System FAQs

How can these batch systems help control my concrete batching process?

How do cloud-based solutions help with data processing?

How does streamlining data help with my batch-processing jobs?

Batch processing is essential for handling frequent, repetitive tasks. By automating these tasks, organizations can minimize human interaction, improve efficiency, and reduce the need for supervision in processes like data analysis.