JuanCrete, Inc. Makes the Best Concrete in the Universe!

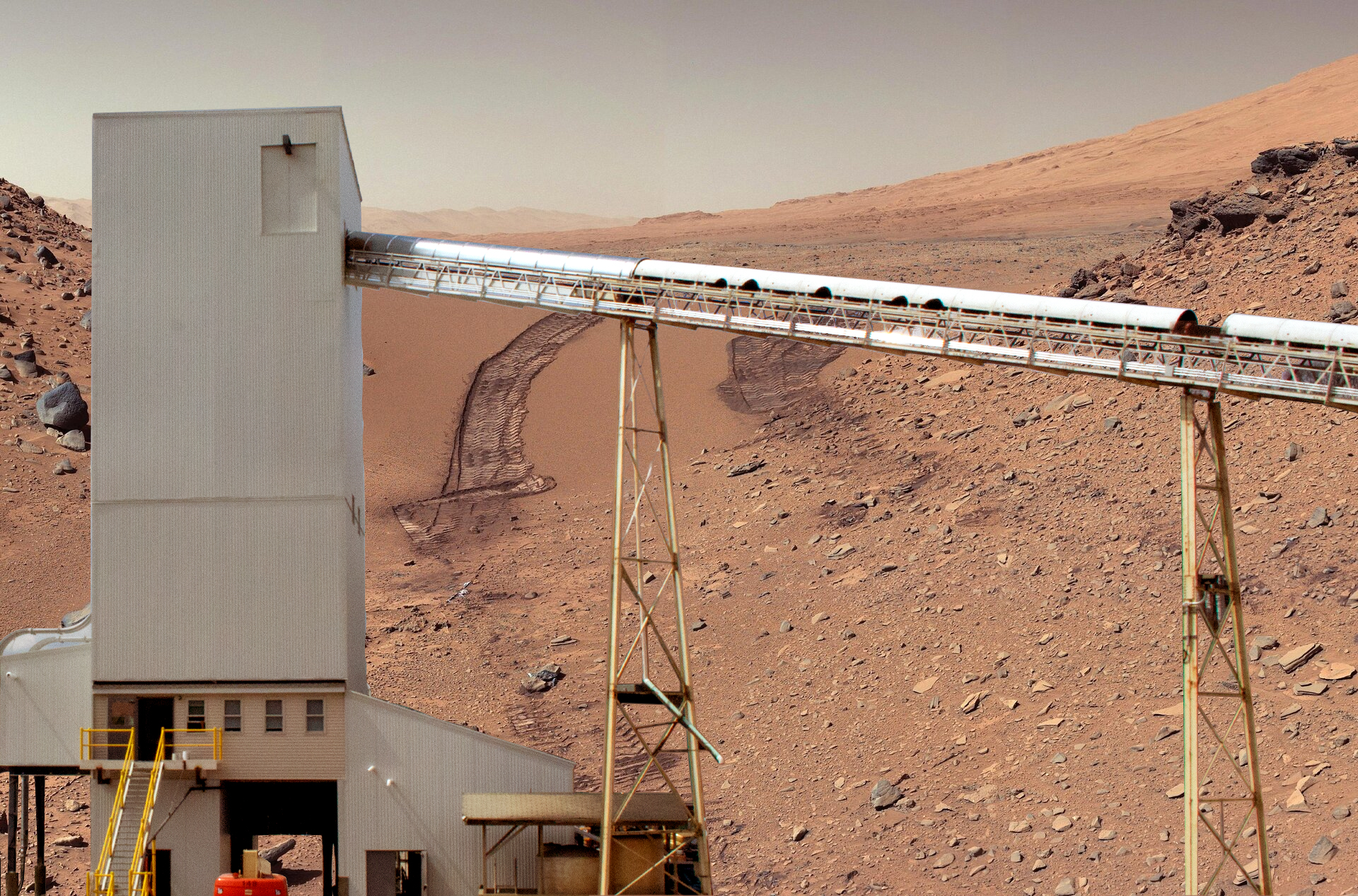

In order for Humans to flourish on Mars, permanent structures were needed to be built. The first was the worst, but things are moving smoothly now. Transporting materials to an environment of this magnitude and robustness would be extremely challenging, so the geo-environmental resources on hand must be utilized. Using this idea, researchers developed a Martian infrastructure material called Marscrete.

Marscrete is the Martian version of traditional sulfur concrete, which is manufactured by melting sulfur and mixing it with sand with approximately a 25-75 mass ratio. Marscrete is made up of 50% sulfur and 50% Martian regolith in its purest form(1). Sulfur is plentiful in compounds on and below the surface of Mars, and regolith is readily available on the planet.

Results from compression strength tests, splitting tensile strength, and fracture tests indicate Marscrete exhibits superior mechanical properties to traditional sulfur concrete and even standard Portland cement concrete.

Using the Sysdyne Product Suite, along with the recently launched Wi-Fi satellites, JuanCrete, Inc. can now produce, transport, and disperse more ready-mixed concrete than anyone could have imagined faster and in greater quantities than ever before! With an average temperature of minus 80 degrees(2), the iStrada® Delivery Management System provides contractors on Mars the ability to track the delivery status of their Marscrete order so that they can remain indoors as long as possible.

The combination of ConcreteGO® and Pioneer® Cloud Batch enables JuanCrete’s martian mixes to be documented easily and prepared with just a fingertip. While they are still developing their third residential complex on Mars, due to a lack of personnel, JuanCrete’s central dispatch/batch location remains on Earth. With their average satellite internet speed at 1Gbps, however, this has not negatively affected operations, as all activities including communication, dispatch and batch control are performed through the cloud.

References

(1) Troemner, M., Ramyar, E., Marrero, R., Mendu, K., & Cusatis, G. (2021, April 15). Marscrete: A Martian Concrete for Additive Construction Applications Utilizing In Situ Resources. Earth and Space 2021. https://ascelibrary.org/

(2) Mars Facts | All About Mars – NASA’s Mars Exploration Program. (2021, February 02). Retrieved July 22, 2022, from https://mars.nasa.gov/