Batching that moves as

fast as your business.

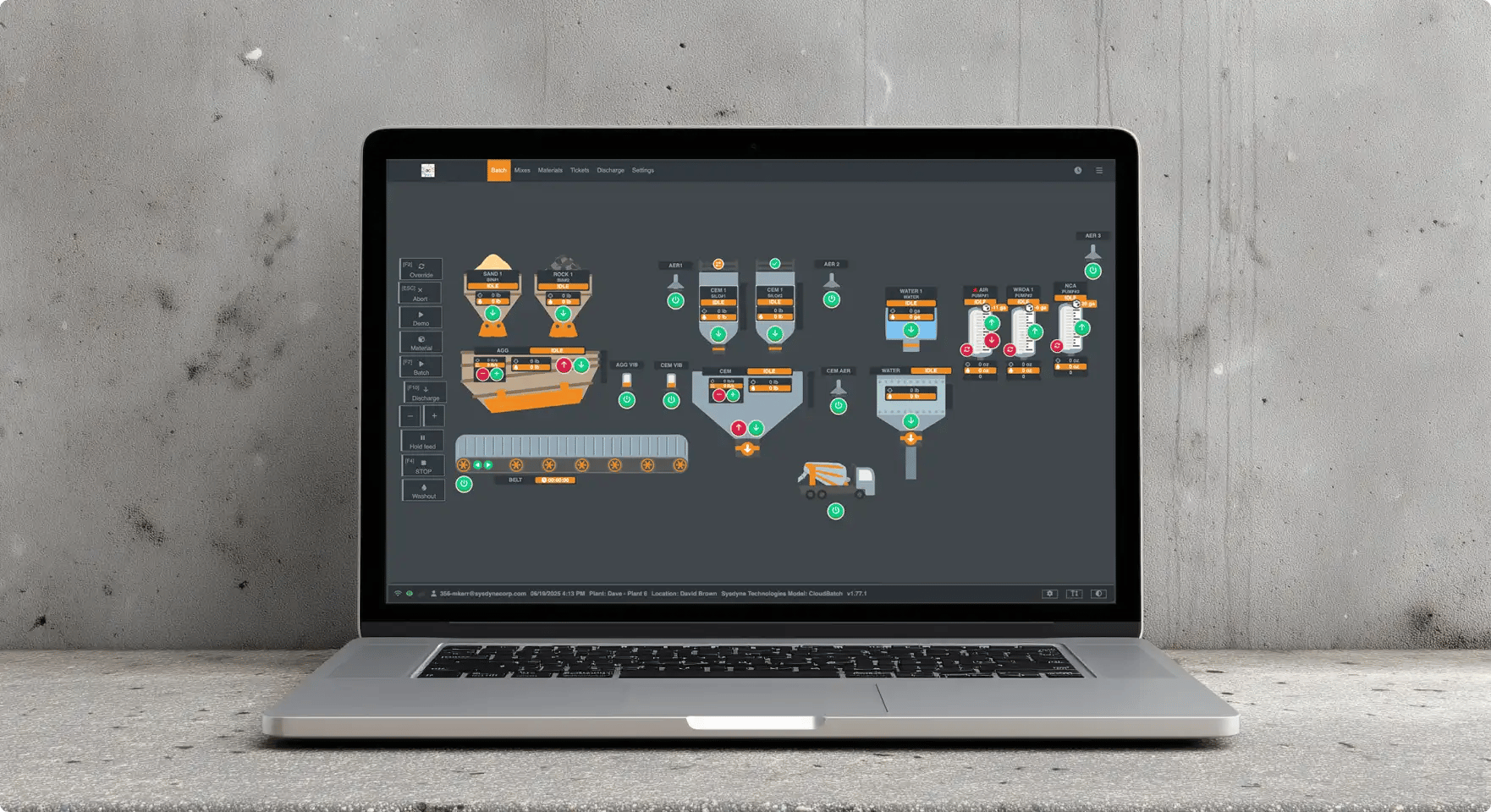

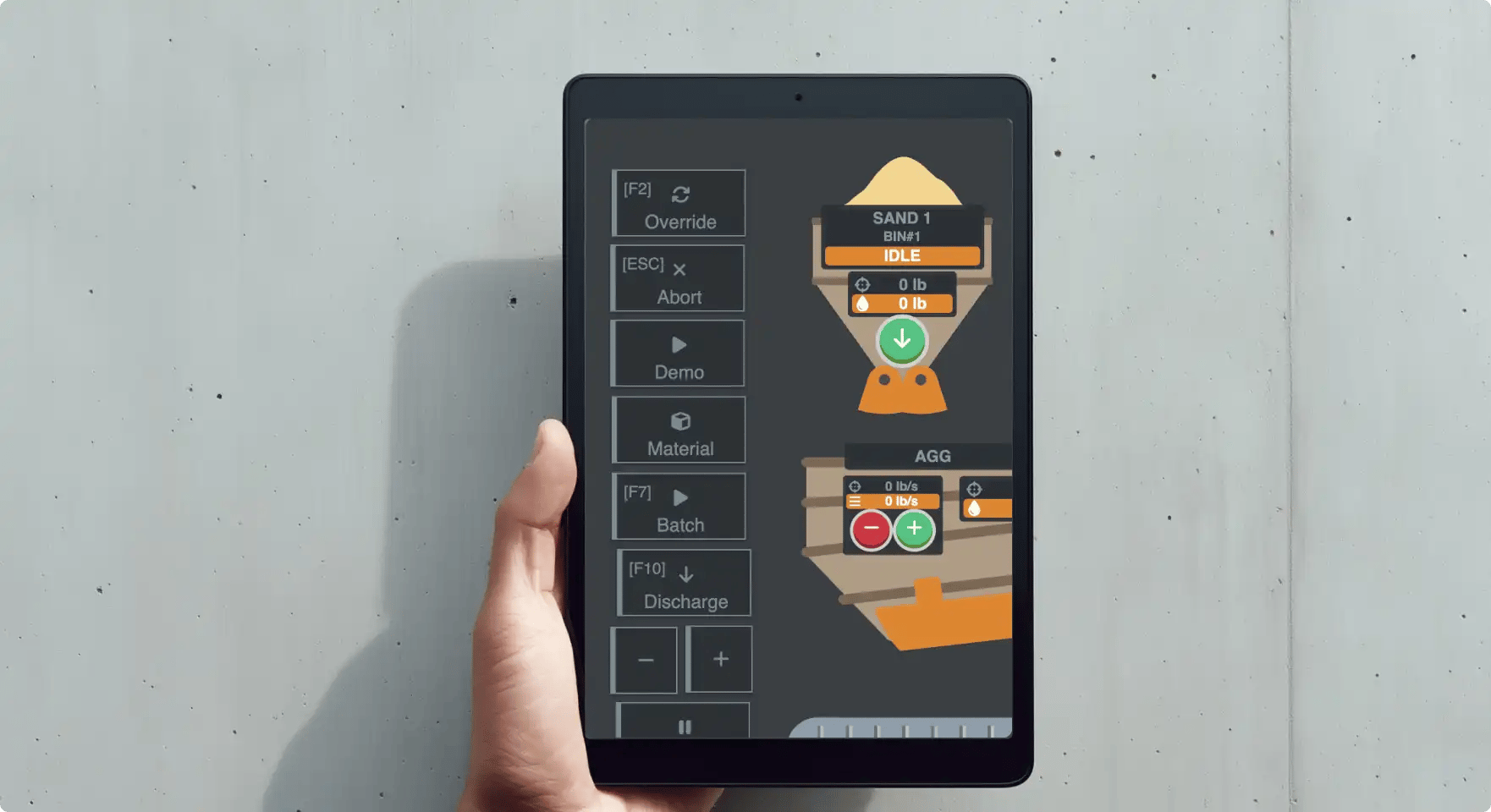

Real-time control. Zero downtime. Batch concrete from anywhere, all you need is a browser. This is the first cloud-native batch control system. Built to save time and designed to cut costs. And now, with BatchGo AI, it just got even smarter.

0

Hardware needed

30M+

Yards dispatched annually

$0.42

Savings per yard

Five simple reasons to get started with the BatchGo real time batching system.

-

Anywhere access

Log in and run your batch plant from any device—no installs, no hassle.

-

One source of truth

Sync batch + dispatch in one place. Everyone sees the same, complete data set.

-

Multi-user ready

Let dispatchers, operators, and managers work together.

-

Unified database

One platform for tickets, orders, materials, customers.

-

Leverage AI to save on materials

Cut waste with tighter control, featuring BatchGo AI. Save up to $0.42 per yard.

Reimagine batching with no downtime.

Platform Overview

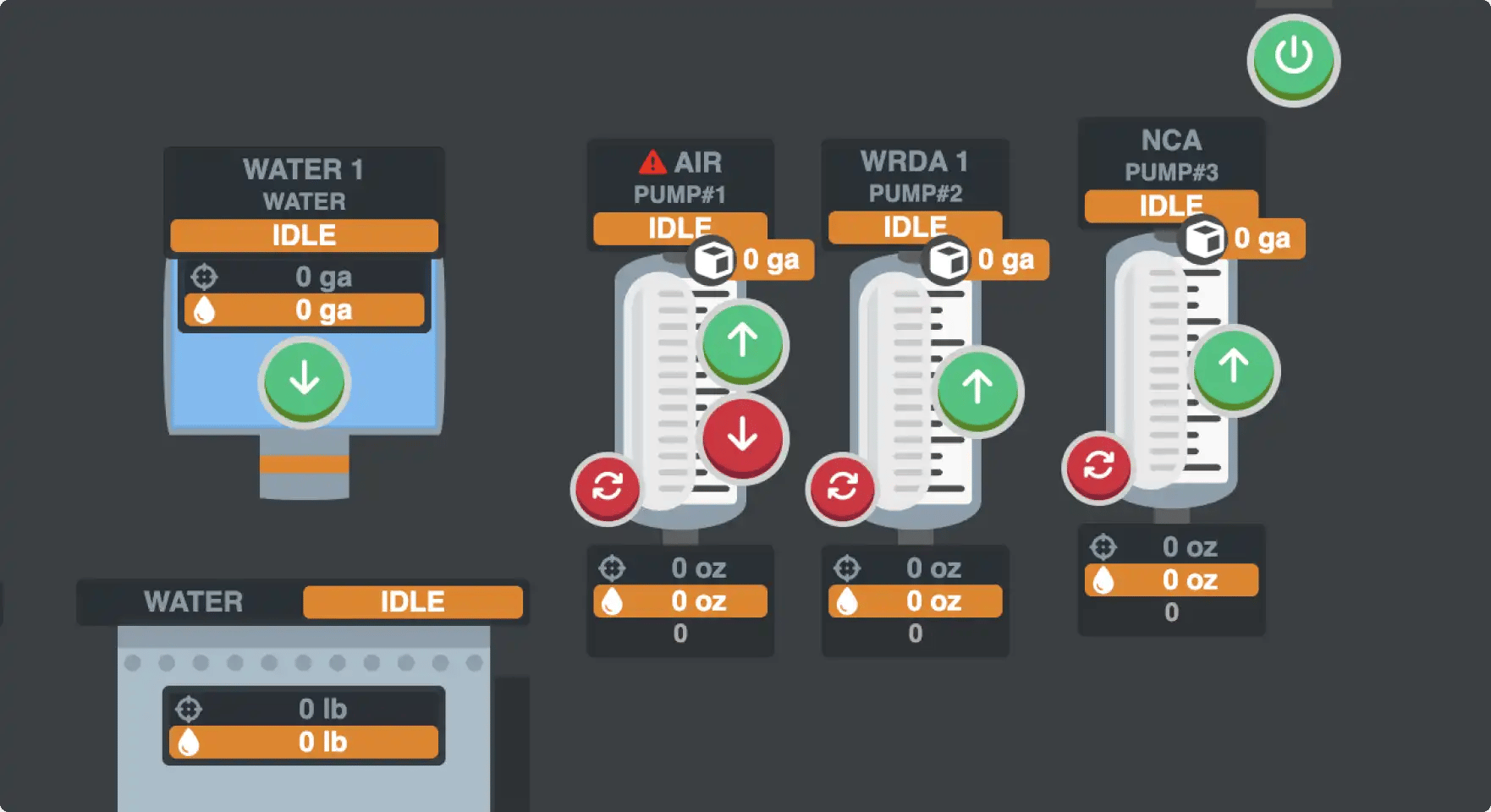

Know what you have—every second.

Real-time material tracking helps plan smarter and avoid shortages. Inventory updates as you load, track receipts, and fulfill orders.

Offline Mode = No Downtime

Internet drops? BatchGo keeps running and syncs tickets once you're back online. Zero disruption. No concrete wasted.

Fix before it fails.

Smart sensors flag problems early, so you avoid shutdowns and unnecessary repairs. Updates install automatically.

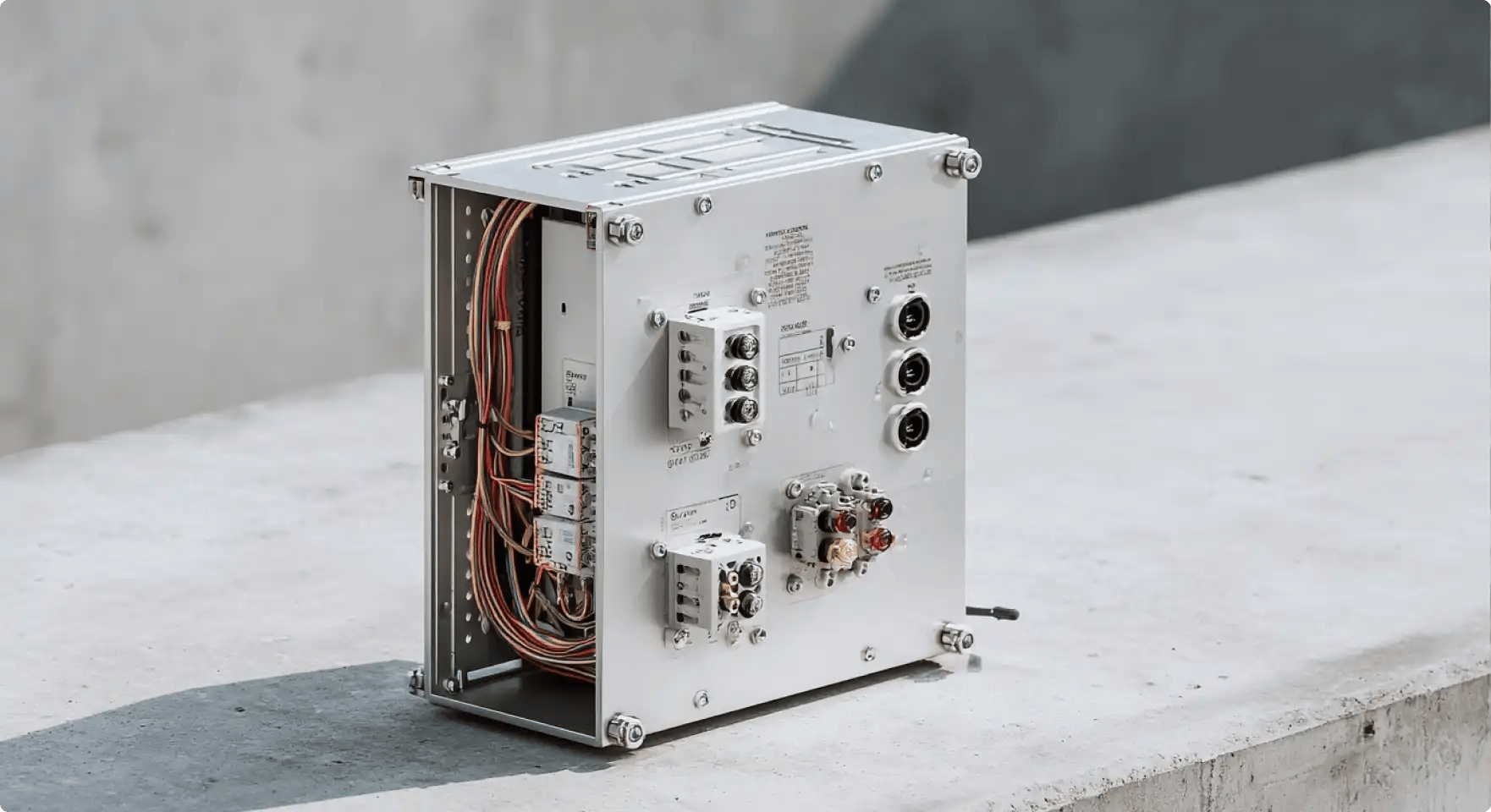

PAC-Controlled. Built to Last.

High-performance Programmable Automation Controllers (PAC) give you speed and reliability. Lifetime warranty optional.

Need to review a load?

Replay any batch like a video. Perfect for quality checks, training, and operational insight.

Take their word for it.

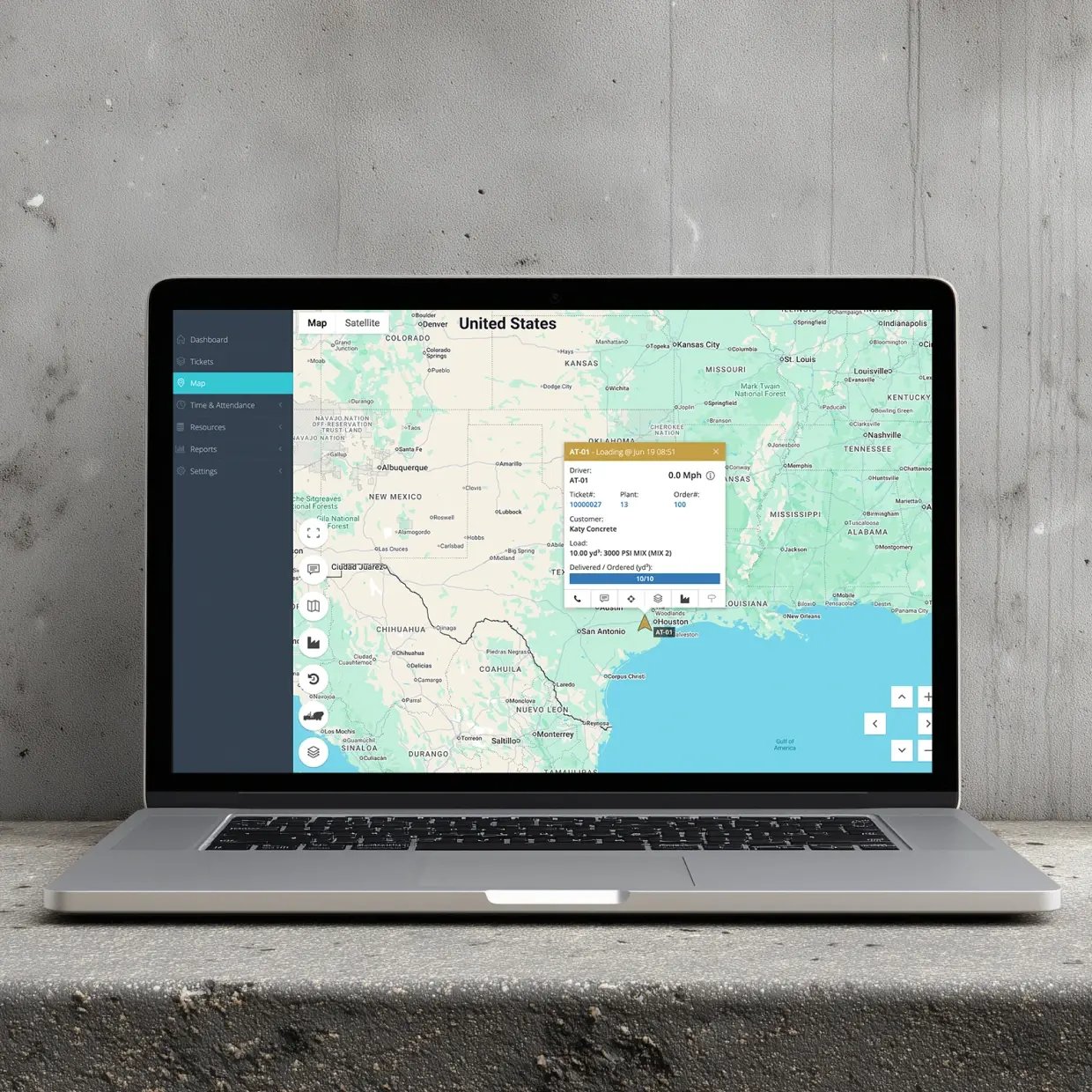

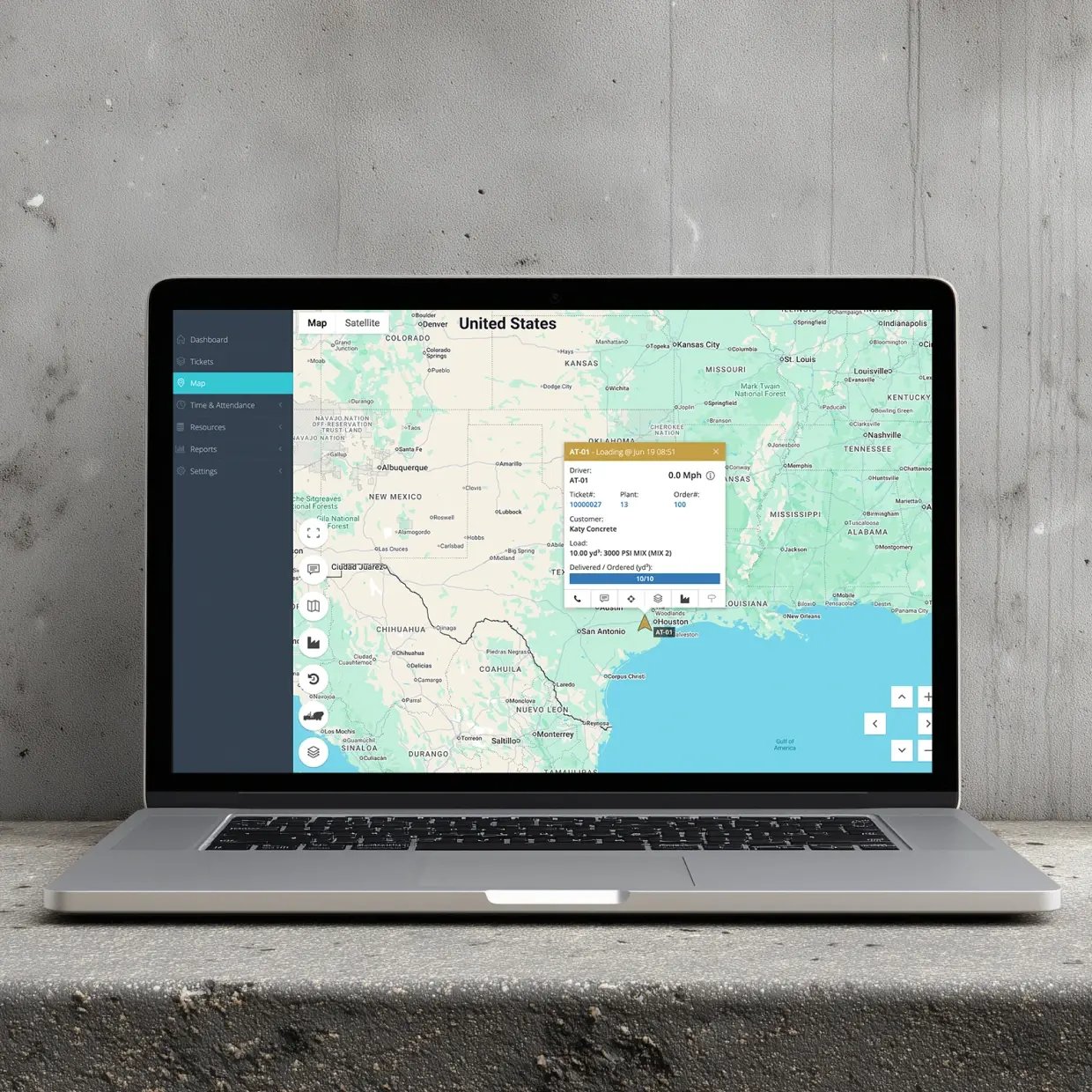

Customer Stories“The geofence and auto-status features have helped cut down radio chatter and back-and-forth between drivers and dispatch. ConcreteGo and DeliveryGo have helped streamline our dispatch and GPS processes.”

Mandi Yureko, Kost Materials

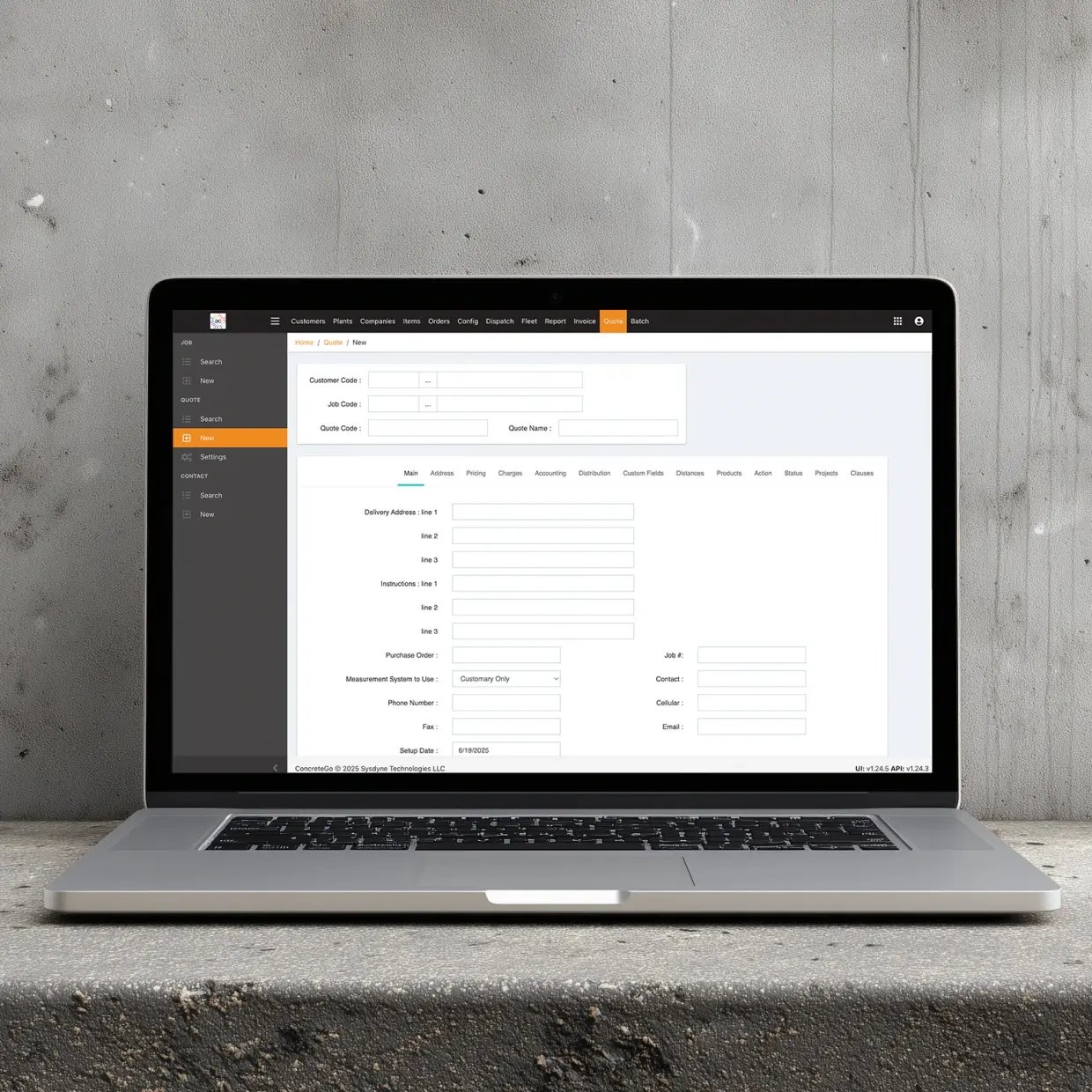

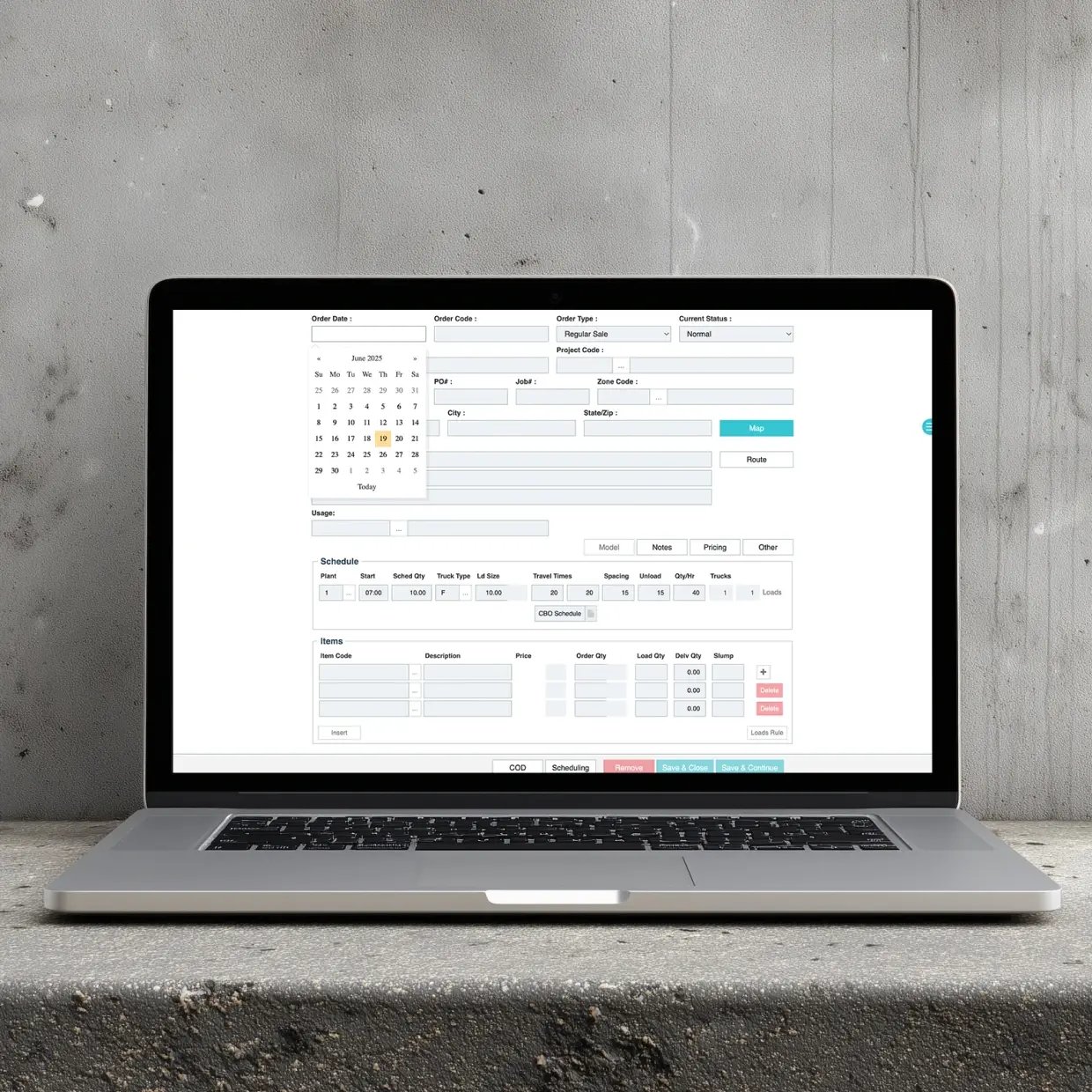

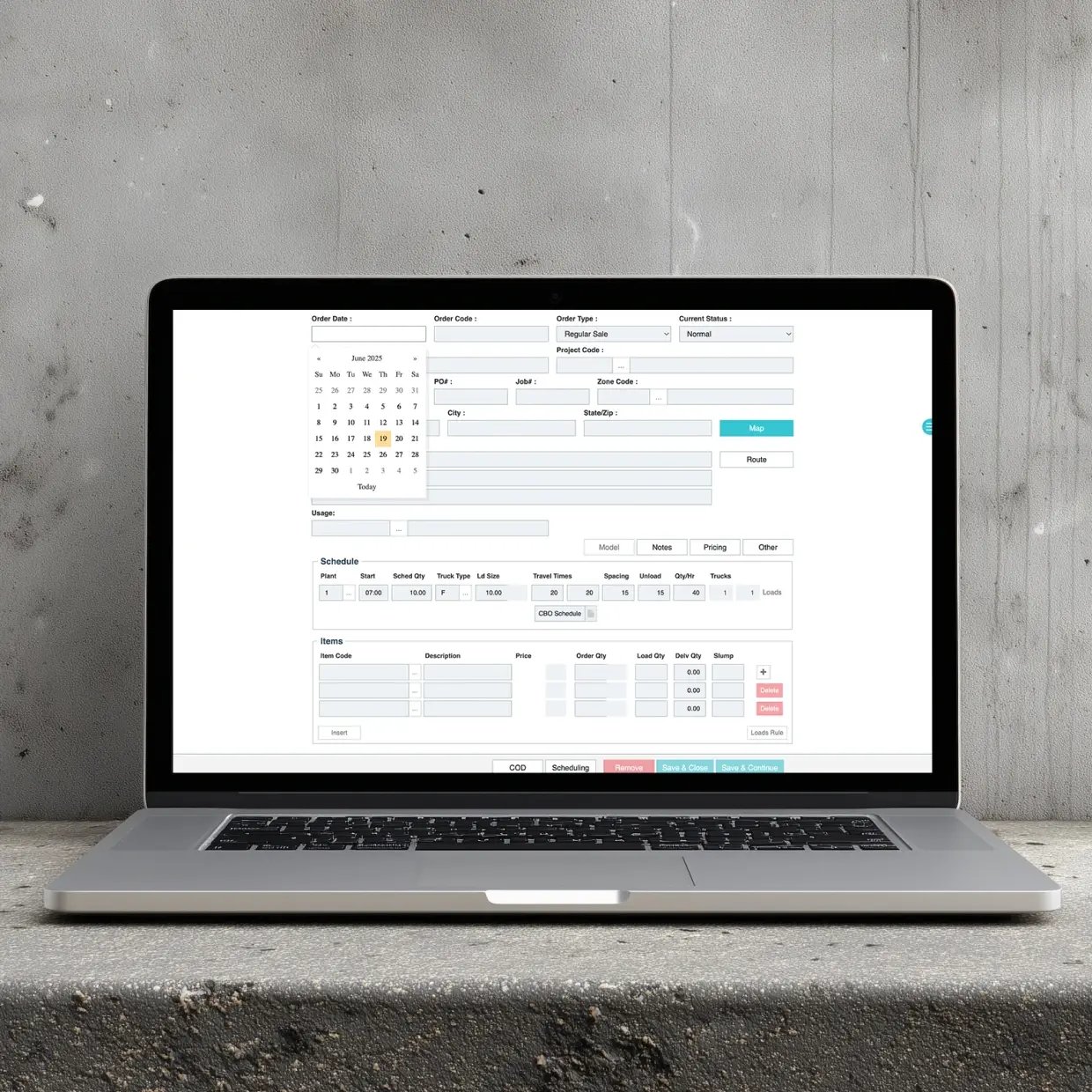

Automate and streamline the sales process.

Experience a streamlined approach to creating accurate, customizable quotes that not only simplify the sales process but also harness the advanced features of ConcreteGo. From real-time data insights to efficient communication, this integrated solution empowers your sales team to deliver precise quotes, enhancing customer satisfaction and driving business success.

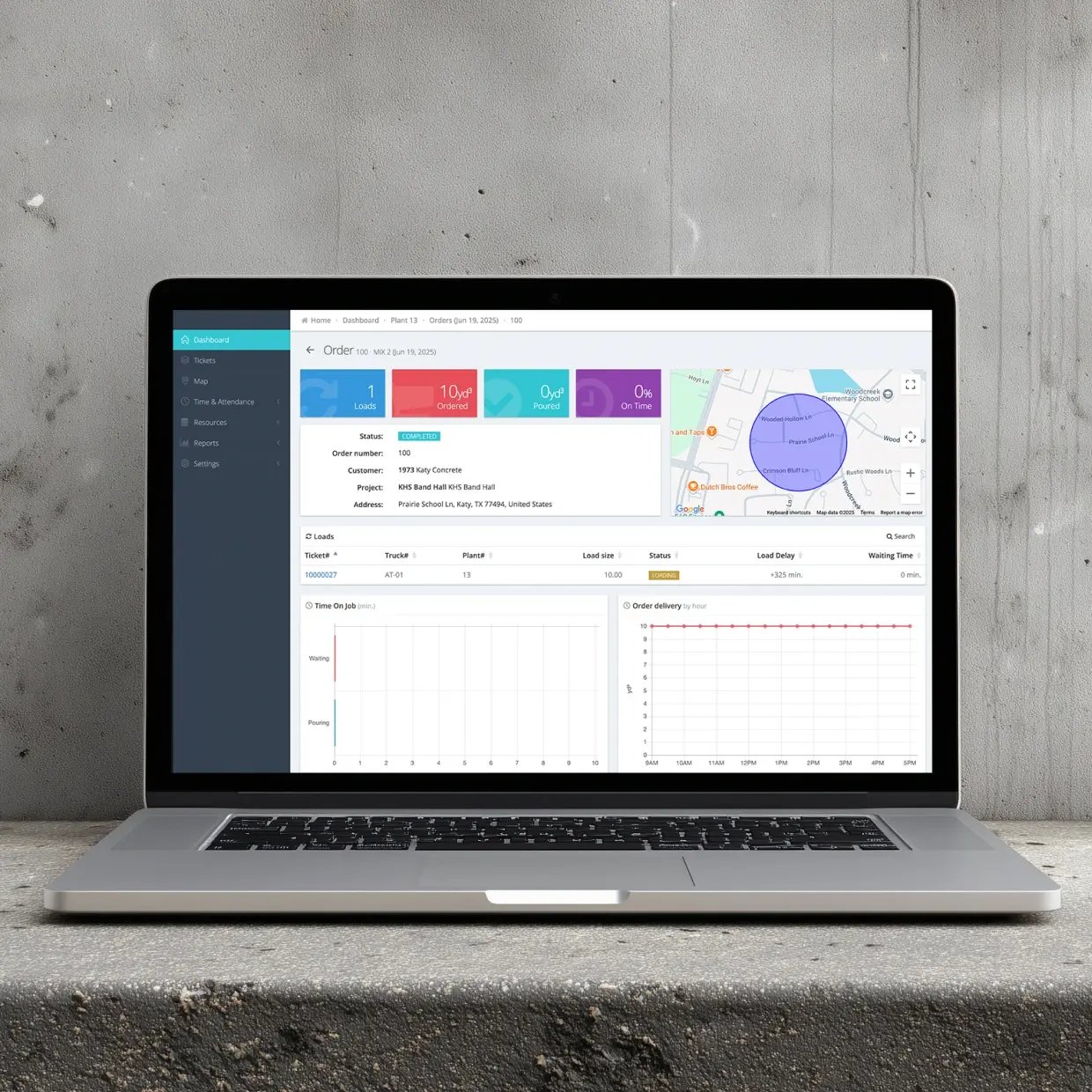

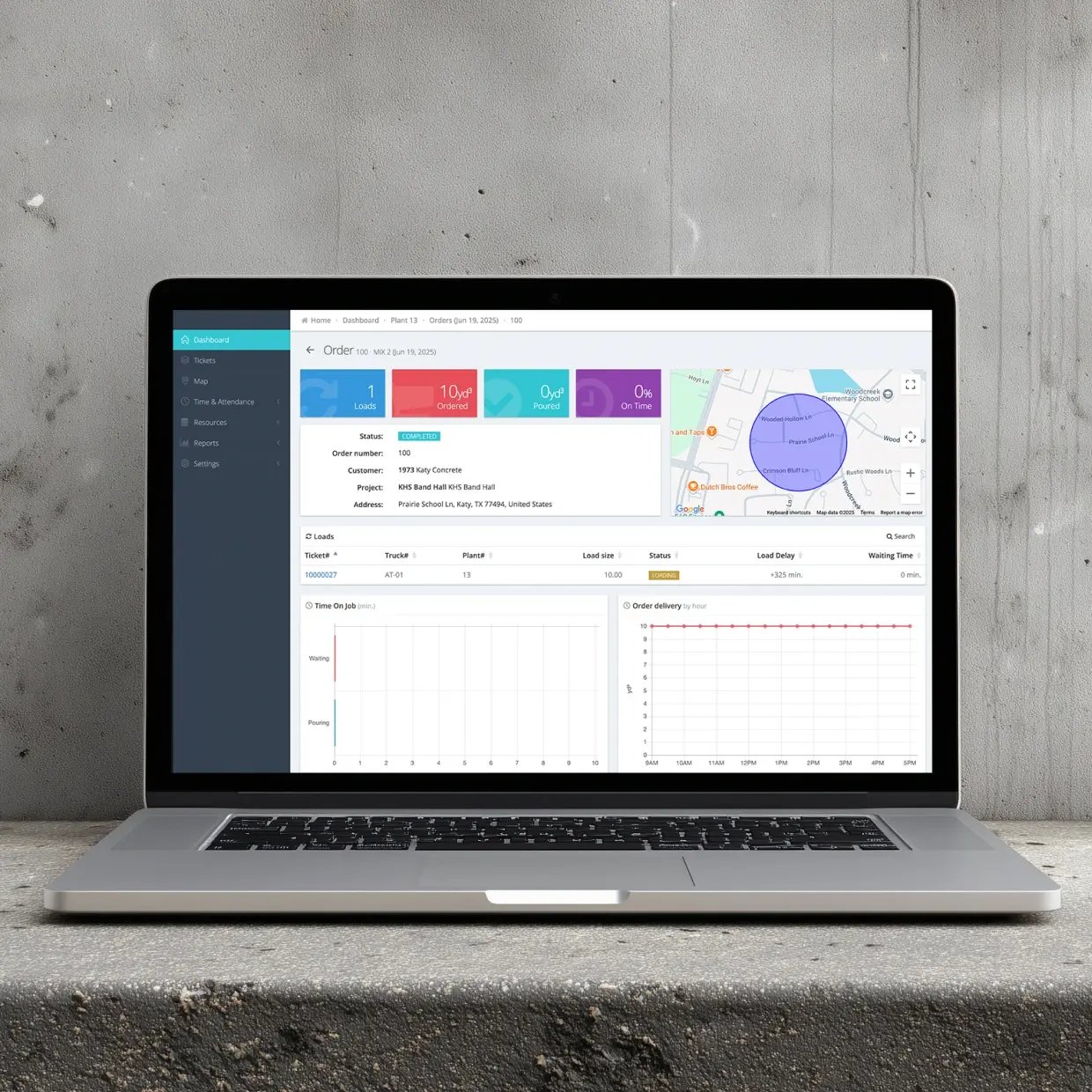

Real time dispatch, so you can save real time.

This is concrete dispatch software for ready-mix producers, without infrastructure headaches. Access your concrete operations anytime from anywhere and manage production and deliveries down to the second.

Batching that moves as fast as your business.

Real-time control. Zero downtime. Batch concrete from anywhere, all you need is a browser. This is the first cloud first batch control system. Built to save time and designed to cut costs.

Move concrete faster by delivering smarter.

Track trucks real-time, go paperless, and keep every job moving—without the calls or chaos. Built for speed. Made for the field, this is smarter concrete delivery.

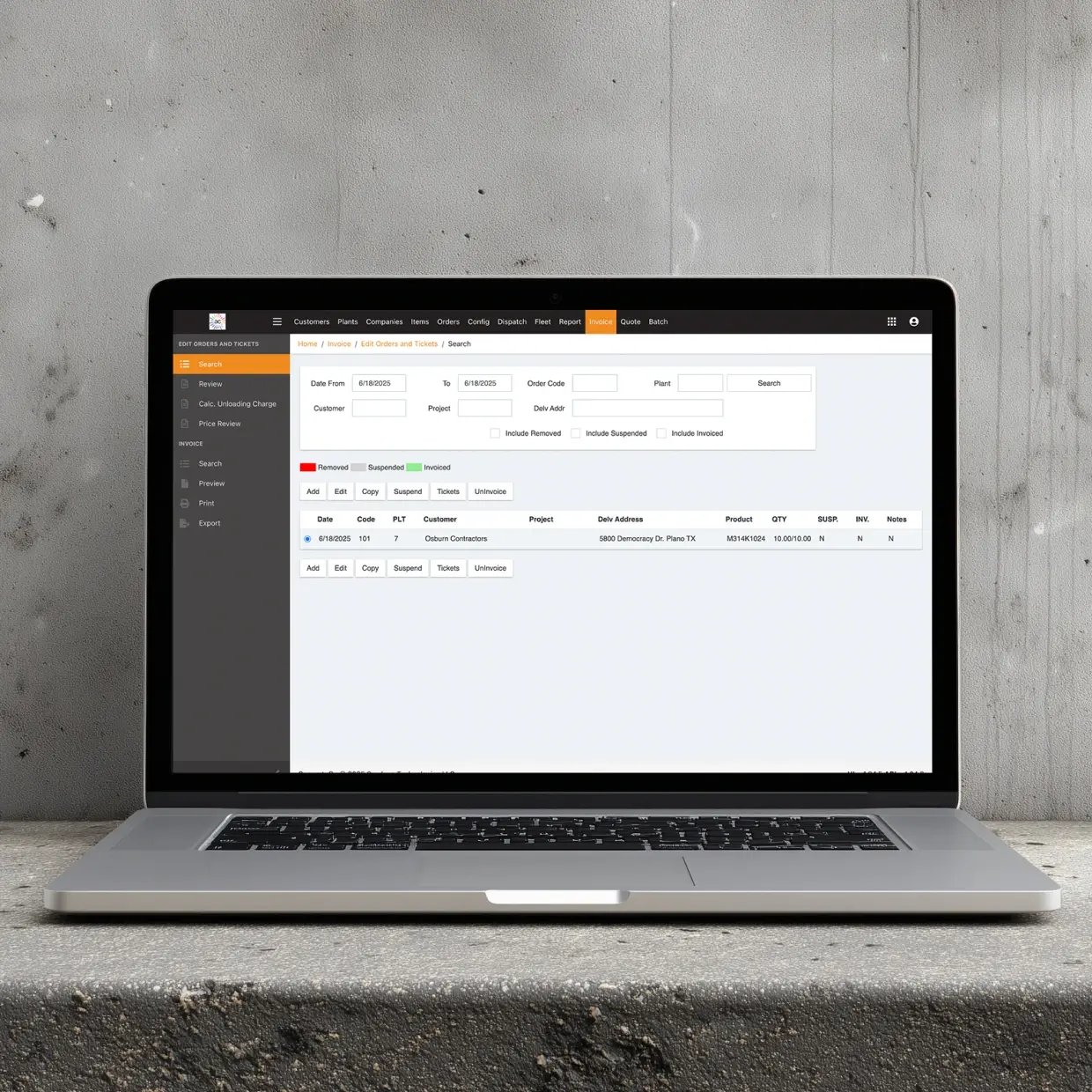

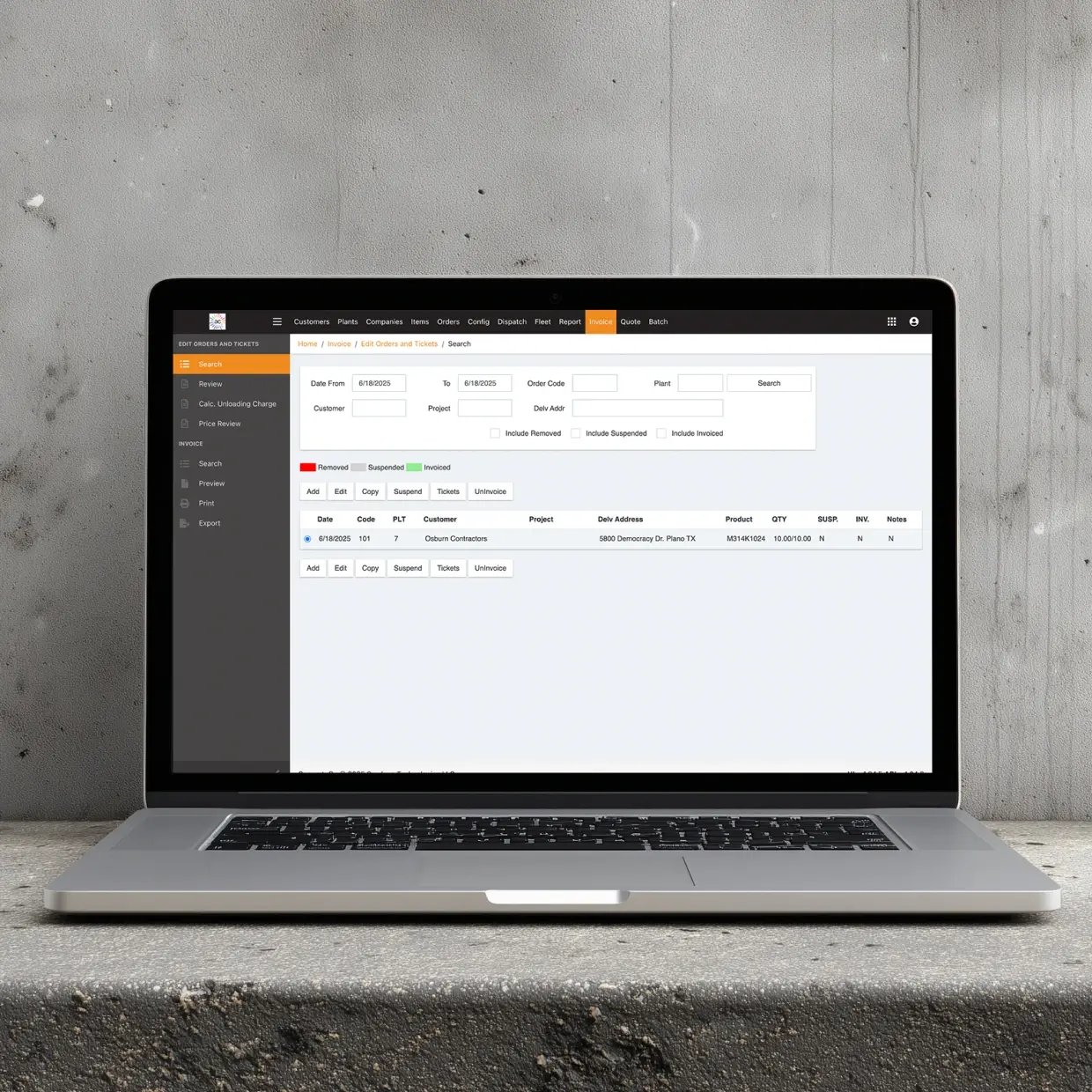

From ticket to invoice in just a few clicks.

QuickLink syncs your dispatch and accounting data—saving hours and boosting billing accuracy. Revolutionize your accounting process with seamless AR and invoicing tools designed for the concrete industry.

Smarter decisions. Faster concrete ops.

Intelligence that puts your concrete business data to work with real time dashboards and smarter insights. InsightGo is free for all Sysdyne users. No hidden fees. No extra software.

Less toggling. More batching.

Sysdyne connects with the tools you already use — so the team saves time, and business runs smoother. From quality control and mix design to business intelligence and optimization, we support all your integrations.