ConcreteGO® Man Hour Report: Compare Driver and Plant Performance To Drive Higher Profits

Sysdyne’s suite of fully integrated batch, dispatch and delivery management applications offer advanced KPI (key performance indicator) reports to measure performance and generate powerful business insights for Concrete producers.

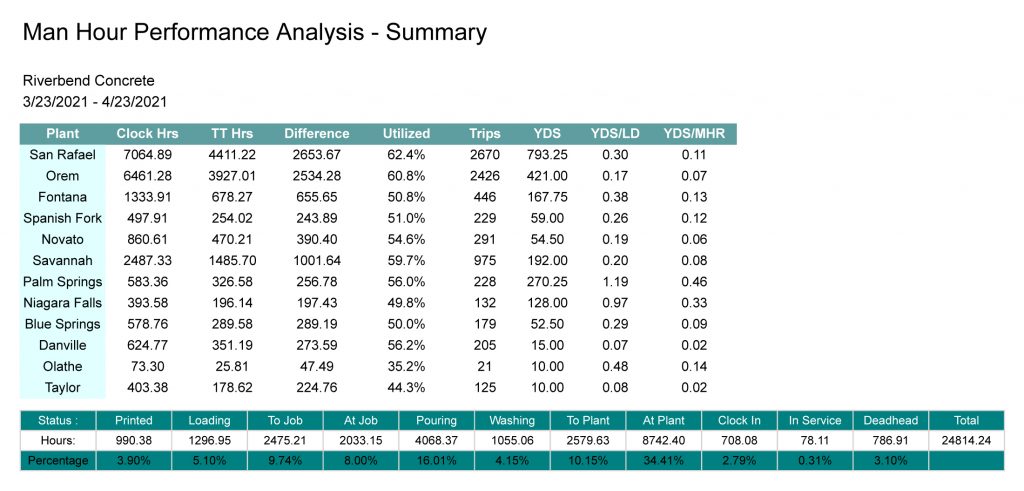

ConcreteGO’s Man/Hour Performance report helps Concrete Producers compare driver and plant performance to set benchmark metrics for their entire operations. Tracking performance metrics like total trip hours (time spent delivering loads) and comparing the number of yards per clocked hour being delivered, is vital for concrete executives and owners to measure profitability and run their quarterly financials effectively.

The man-hour performance analysis helps Ready-Mix producers determine the level of efficiency of their delivery cycles and the efficiency per man on the job among other things. Some concrete industry people might also call it dispatch efficiency. The % Truck Utilization metric = driver hours worked – driver standby hours)/driver hours worked. Why is this important? We know the 2nd highest cost in a cubic yard of concrete is the delivery cost. How am I doing with the rest of the ready-mix producers? NRMCA’s past statistics show the avg % Truck utilization as high as 94% and some as low as 59%. If the % of truck utilization is low, I am calling more drivers to come to work, and we don’t have enough orders to deliver.

The Yards per Man Hour metric represents the ratio of cubic meters/cubic yards of concrete delivered in relation to the amount of driver or clock hours for the given period. This ratio is an essential benchmark because it indicates driver efficiency and can affect bottom-line results and operational efficiency. The NRMCA reported in their 2019 Industry Performance NRMCA Annual Conference that the industry average for Yards per Man Hour ranges from 2.9 yards to 3.2 yards per man-hour. The rule of thumb is that the higher the ratio number, the better the operational efficiency.

The YDS/LD metric, otherwise known as Average Load Size is the ratio of the cubic yards/cubic meters delivered in relation to the total number of trips a given period. As a reference, if every truck that had a ten-yard/meter capacity delivered full loads, the Yards per Load would be 10. Yards per load is an essential measure of truck utilization. The 2020 NRMCA Fleet Benchmarking and Costs Survey indicated that the industry average for YDS/LD is 8.3 cubic yards per load. Enhancing the Yards per Load will help increase delivery efficiency and potentially increase the number of deliveries that can be made in a day based on the truck resources.

Definitions:

• TT: total trip hours, time spent delivering the load

• Difference: Difference between clocked hours and TT hours

• Utilized: Total trip hours divided by clocked hours, to see % time spent delivering a load

• Trips: The number of tickets or loads

• YDS: Yards delivered

• YDS/LD: Average load size

• YDS/MHR: Total yards divided by clocked hours, how many yards per clocked hours are we delivering

Retrieved from: Concrete Infocus – “2020 NRMCA Fleet Benchmarking And Costs Survey”